filmov

tv

How carbide inserts are made by Sandvik Coromant

Показать описание

Carbide inserts are used to machine almost everything made of metal. The insert has to withstand extreme heat and force, so it’s made of some of the hardest material in the world.

We take you to the Sandvik Coromant's world class insert production facility at Gimo, Sweden to witness how an insert is made. See how it's done!

Transcript

Almost everything made of metal is machined with an insert. The insert has to withstand extreme heat and force, so it’s made of some of the hardest material in the world.

A typical insert is made of 80% tungsten carbide and a metal matrix that binds the hard carbide grains together, where cobalt is the most common. It takes more than two days to produce an insert, so it’s a complicated process.

In the material warehouse, row after row of raw material are stacked. The tungsten carbide we use is either recycled, or comes from our own mine in Austria. Cobalt, titanium and all other ingredients come from carefully selected suppliers; each batch meticulously tested in the lab.

Some recipes contain very small amounts of selected ingredients that are added by hand. The main ingredients are then automatically dispensed at the different stops along the weigh line.

In the milling room the ingredients are milled to the required particle size together with ethanol, water and an organic binder. This process takes from eight to 55 hours, depending on the recipe.

The slurry is pumped into a spray drier where hot nitrogen gas is sprayed to evaporate the ethanol and water mixture. When the powder is dry, it consists of spherical granules of identical sizes. A sample is sent to the lab for quality check.

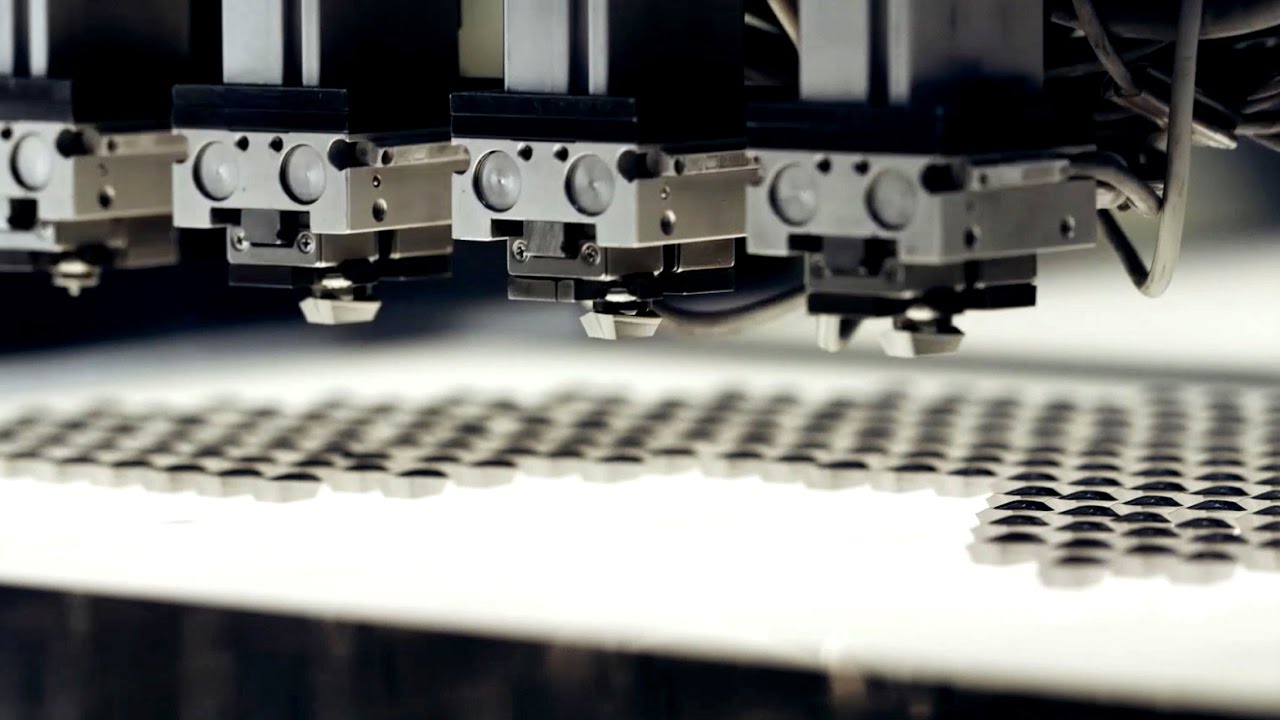

Barrels of 100 kilograms of ready-to-press powder arrive at the pressing machine. The binder added in the milling room is the binder that holds the powder together after pressing. Up to 12 tons of pressure are applied, depending on the type of insert. The binder added in the milling room is what holds the powder together after pressing. The process is completely automated. Each insert is weighed and at certain intervals controlled visually by the operator.

The pressed inserts are very fragile and need to be hardened in a sintering oven. This process takes about 13 hours at a temperature of approximately 1,500 degrees Celsius. The inserts are sintered into an extremely hard cemented-carbide product, almost as hard as diamond. The organic binder is incinerated and the insert shrinks approximately to half its original size. The excess heat is recycled and used to heat the premises in the winter, and cool them down during summer.

The inserts are ground, one by one, in different types of grinding machines to achieve the exact size, geometry and tolerances. As the cemented carbide insert is so hard, a disc with 150 million small industrial diamonds, is used to grind it. The excess carbide is recycled, as well as the oil that is used as cutting fluid.

The majority of inserts are coated, either through chemical vapour deposition (CVD) or physical vapour deposition (PVD). Here, we see a PVD-process.

The inserts are placed in fixtures...

…and put into the oven.

The thin layer of coating makes the insert both harder and tougher. This is also where the insert gets its specific colour.

Although the insert has been inspected at the lab regularly during the whole process, it’s manually examined again before it’s laser marked and packed.

After labelling, the grey boxes are ready to be sent out to manufacturers around the world.

When the inserts are worn out, they are returned to Sandvik Coromant for recycling, and the process of making a new insert begins.

We take you to the Sandvik Coromant's world class insert production facility at Gimo, Sweden to witness how an insert is made. See how it's done!

Transcript

Almost everything made of metal is machined with an insert. The insert has to withstand extreme heat and force, so it’s made of some of the hardest material in the world.

A typical insert is made of 80% tungsten carbide and a metal matrix that binds the hard carbide grains together, where cobalt is the most common. It takes more than two days to produce an insert, so it’s a complicated process.

In the material warehouse, row after row of raw material are stacked. The tungsten carbide we use is either recycled, or comes from our own mine in Austria. Cobalt, titanium and all other ingredients come from carefully selected suppliers; each batch meticulously tested in the lab.

Some recipes contain very small amounts of selected ingredients that are added by hand. The main ingredients are then automatically dispensed at the different stops along the weigh line.

In the milling room the ingredients are milled to the required particle size together with ethanol, water and an organic binder. This process takes from eight to 55 hours, depending on the recipe.

The slurry is pumped into a spray drier where hot nitrogen gas is sprayed to evaporate the ethanol and water mixture. When the powder is dry, it consists of spherical granules of identical sizes. A sample is sent to the lab for quality check.

Barrels of 100 kilograms of ready-to-press powder arrive at the pressing machine. The binder added in the milling room is the binder that holds the powder together after pressing. Up to 12 tons of pressure are applied, depending on the type of insert. The binder added in the milling room is what holds the powder together after pressing. The process is completely automated. Each insert is weighed and at certain intervals controlled visually by the operator.

The pressed inserts are very fragile and need to be hardened in a sintering oven. This process takes about 13 hours at a temperature of approximately 1,500 degrees Celsius. The inserts are sintered into an extremely hard cemented-carbide product, almost as hard as diamond. The organic binder is incinerated and the insert shrinks approximately to half its original size. The excess heat is recycled and used to heat the premises in the winter, and cool them down during summer.

The inserts are ground, one by one, in different types of grinding machines to achieve the exact size, geometry and tolerances. As the cemented carbide insert is so hard, a disc with 150 million small industrial diamonds, is used to grind it. The excess carbide is recycled, as well as the oil that is used as cutting fluid.

The majority of inserts are coated, either through chemical vapour deposition (CVD) or physical vapour deposition (PVD). Here, we see a PVD-process.

The inserts are placed in fixtures...

…and put into the oven.

The thin layer of coating makes the insert both harder and tougher. This is also where the insert gets its specific colour.

Although the insert has been inspected at the lab regularly during the whole process, it’s manually examined again before it’s laser marked and packed.

After labelling, the grey boxes are ready to be sent out to manufacturers around the world.

When the inserts are worn out, they are returned to Sandvik Coromant for recycling, and the process of making a new insert begins.

Комментарии

0:06:20

0:06:20

0:00:16

0:00:16

0:55:28

0:55:28

0:01:07

0:01:07

0:00:07

0:00:07

0:08:44

0:08:44

0:00:55

0:00:55

0:00:52

0:00:52

0:00:16

0:00:16

0:00:10

0:00:10

0:01:23

0:01:23

0:00:06

0:00:06

0:00:43

0:00:43

0:28:09

0:28:09

0:00:55

0:00:55

0:00:11

0:00:11

0:00:31

0:00:31

0:16:36

0:16:36

0:00:11

0:00:11

0:03:15

0:03:15

0:01:12

0:01:12

0:02:23

0:02:23

0:00:20

0:00:20

0:00:17

0:00:17