filmov

tv

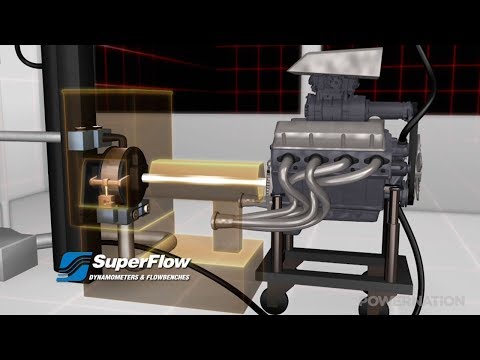

Full Load Dynomometer Test on Electric Motor - Global Electronic Services

Показать описание

Once a motor repair is complete, our technicians perform a full load test using a dynomometer. Watch our video to learn how our repair techs ensure the motor is performing to OEM specs. At Global Electronic Services, your equipment is important to us, which is why we make sure to test each motor after repair for full performance ability. We believe in the best quality at the best price, with incredible turnaround!

Video transcript:

At Global Electronic Services, we utilize our in-house dyno to perform a full load test using a motors rated rpms voltage

and horsepower in order to ensure that the motor will perform at its maximum rated potential. Once the repair of a motor is complete,

it is ready to be fully load tested on one of our dynamometers. The dyno works by using a water break inside to counter the motor shaft. The energy is dissipated as heat into the water. We control torque rise until the motor performs at it's rated horsepower. The

technician will bolt down the motor to the dyno use a coupling to attach the motor, shackle the yoke to the coupling, use dial calipers to ensure the motor and the dyno are within balance of each

other.

As the dynamic load increases, we will monitor the amperage to ensure the motor is not drawing excessive current. The dyno will take samples a few times per second to give us a clear reading that the motor is performing to OEM specs. You can see on the screen as the motor approaches its full performance load. Global Electronic Services believes in the best quality at the best price in the quickest turnaround. Please let us know if you have any questions. We are here 24/7 to help you.

Video transcript:

At Global Electronic Services, we utilize our in-house dyno to perform a full load test using a motors rated rpms voltage

and horsepower in order to ensure that the motor will perform at its maximum rated potential. Once the repair of a motor is complete,

it is ready to be fully load tested on one of our dynamometers. The dyno works by using a water break inside to counter the motor shaft. The energy is dissipated as heat into the water. We control torque rise until the motor performs at it's rated horsepower. The

technician will bolt down the motor to the dyno use a coupling to attach the motor, shackle the yoke to the coupling, use dial calipers to ensure the motor and the dyno are within balance of each

other.

As the dynamic load increases, we will monitor the amperage to ensure the motor is not drawing excessive current. The dyno will take samples a few times per second to give us a clear reading that the motor is performing to OEM specs. You can see on the screen as the motor approaches its full performance load. Global Electronic Services believes in the best quality at the best price in the quickest turnaround. Please let us know if you have any questions. We are here 24/7 to help you.

Комментарии

0:03:00

0:03:00

0:08:01

0:08:01

0:01:09

0:01:09

0:00:33

0:00:33

0:02:03

0:02:03

0:03:33

0:03:33

0:00:28

0:00:28

0:00:54

0:00:54

0:00:19

0:00:19

0:02:11

0:02:11

0:01:32

0:01:32

0:01:23

0:01:23

0:49:12

0:49:12

0:02:57

0:02:57

0:04:05

0:04:05

0:01:27

0:01:27

0:01:54

0:01:54

0:01:06

0:01:06

0:01:41

0:01:41

0:02:38

0:02:38

0:10:37

0:10:37

0:01:59

0:01:59

0:07:37

0:07:37

0:00:29

0:00:29