filmov

tv

D-Cycle engine || IC Engine ||

Показать описание

D - CYCLE ENGINE BY VAN ENGINES

YAN Engines is a small technology company with offices both in Austin, Texas, and Brighton, UK. The company is focused on the development of its own proprietary high-efficiency engine concept that aims to provide significantly enhanced flexibility over the conventional four-stroke internal combustion engine architecture.

The differential stroke cycle piston (D-Cycle) concept relies on a split piston that completes the four engine strokes in a single crankshaft revolution, thus providing the opportunity to reduce the cyclic energy losses and improve combustion process efficiency

|| please Like share and SUBSCRIBE 🙏 😊 please 🙏 😊 ||

YAN Engines is a small technology company with offices both in Austin, Texas, and Brighton, UK. The company is focused on the development of its own proprietary high-efficiency engine concept that aims to provide significantly enhanced flexibility over the conventional four-stroke internal combustion engine architecture.

The differential stroke cycle piston (D-Cycle) concept relies on a split piston that completes the four engine strokes in a single crankshaft revolution, thus providing the opportunity to reduce the cyclic energy losses and improve combustion process efficiency

|| please Like share and SUBSCRIBE 🙏 😊 please 🙏 😊 ||

Perfect Combination Of 4 Stroke & 2 Stroke Engine | D-Cycle Engine (UHD 4K)

D-Cycle Engine | IC Engine📌 #engine#automobile#automotive#combustionengine @engineeringmodel

Analyzing The Split Piston Engine in 3D. 🤯 Dual Cycle D // 2 and 4 Strokes Combined // 3D Animation...

'D-Cycle Engine Design Explained | How This Revolutionary Engine Works'*

Atkinson Cycle Engine

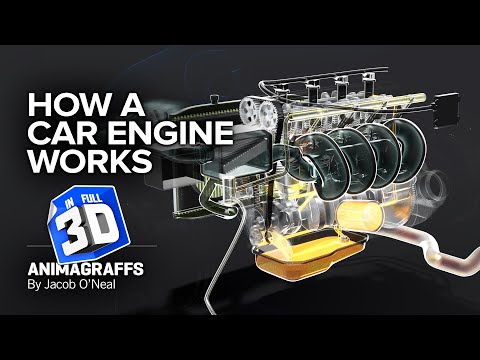

How a Car Engine Works

D-Cycle engine || IC Engine ||

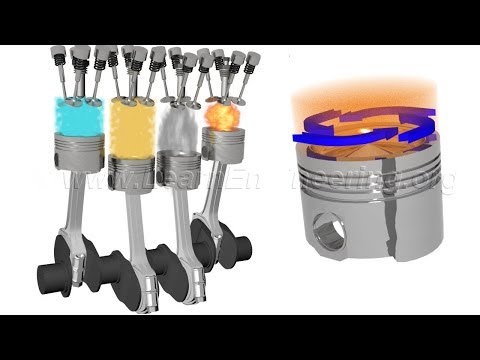

How car engine works? / 4 stroke internal combustion engine (3D animation)

2 Stroke Vs 4 Stroke engine! INTERNAL COMBUSTION ENGINE #engine#automobile#automotive#engine#fuel#3d

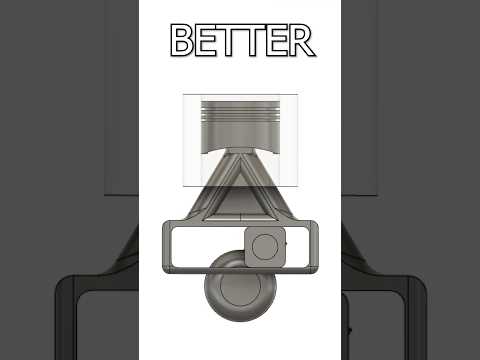

How To Work Engine Piston 🔥

diesel (compression ignition)engine working .... diesel cycle

Two stroke vs Four stroke engine #shortsvideo #automotive #automobile #engineering #engine

You'll understand everything about Atkinson, Miller and Otto cycle engines after watching this ...

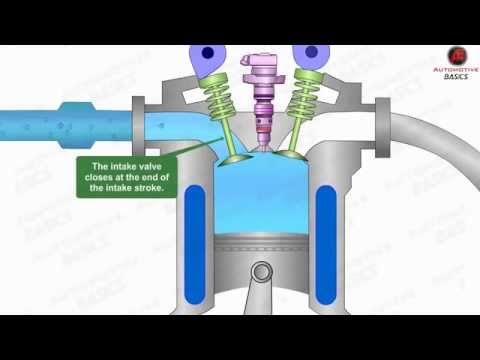

How Does an Internal Combustion Engine Work?

Combine 4 Stroke & 2 Stroke engine | D-Cycle Engine #3d #design #animation #4stroke #2stroke #en...

What's the name of the second engine? #engineering #engine #hp #power #d4a #thumper #jdm #toyot...

four stroke motor sound animation engine #shorts #viral #mechanical #animation

Piston movement in the cylinder on engine #shorts

How Diesel Engines Work - Part - 1 (Four Stroke Combustion Cycle)

Testing Engine

How a Diesel Engine Works

Diesel Engine, How it works ?

D-Cycle Piston by YAN ENGINES

Otto vs Atkinson cycle engine #toyota #shorts #automobile

Комментарии

0:06:18

0:06:18

0:00:10

0:00:10

0:09:01

0:09:01

0:00:07

0:00:07

0:02:41

0:02:41

0:07:55

0:07:55

0:00:36

0:00:36

0:09:52

0:09:52

0:00:09

0:00:09

0:00:21

0:00:21

0:00:25

0:00:25

0:00:10

0:00:10

0:22:39

0:22:39

0:03:31

0:03:31

0:00:15

0:00:15

0:00:10

0:00:10

0:00:07

0:00:07

0:00:30

0:00:30

0:04:14

0:04:14

0:00:18

0:00:18

0:01:58

0:01:58

0:06:20

0:06:20

0:00:36

0:00:36

0:00:09

0:00:09