filmov

tv

Stringers vs Weaves

Показать описание

#welddotcom

How to win friends and influence welders... Compare stringers vs weaves...

Today's episode will likely cause some unruly comments, but we are testing the tensile strength and toughness of stringer beads versus weaves on a 3/4" test plate. The team up at Select Arc is going to help us by doing a tensile pull, as well as a charpy v notch test. Let us know how you feel about the results below!

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK. EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

How to win friends and influence welders... Compare stringers vs weaves...

Today's episode will likely cause some unruly comments, but we are testing the tensile strength and toughness of stringer beads versus weaves on a 3/4" test plate. The team up at Select Arc is going to help us by doing a tensile pull, as well as a charpy v notch test. Let us know how you feel about the results below!

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK. EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

Stringers vs Weaves

Weaving is Better than Stringer Beads? | Stick Welding

Multipass Stringer beads -vs- Weave beads, whats the difference and how to do both.

🔥 Stringer Beads vs Weaving: Bend Test and Etch

Stringers VS Weaves #welding

Stringers vs Weaves #welding #shorts

🔥 WELDING BEAD TECHNIQUES, STRINGER OR WEAVE?

Welding Straight VS Weaving Or Wave | Flux Core Welding For Beginners |

Free Hand Stringers Vs Walk The Cup Weaves on 6G #welding #shorts

Stringer Bead!

6G Pipe Welding - Free hand stringers Vs. weave walking the cup

Stringers vs weaves #howto #fabrication #pipewelder #pipeliner #pipeline #weldeverydamnday

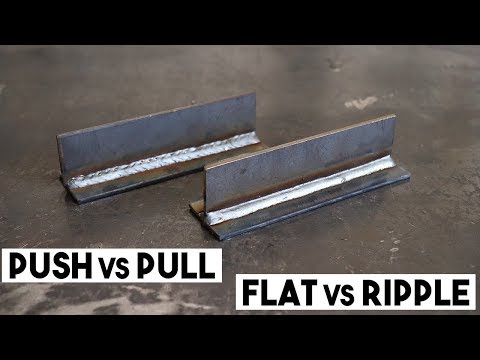

SHOULD YOU PUSH OR PULL A MIG WELD? FLAT OR RIPPLE BEAD?

7018 Stick Welding Practice: Does the WEAVE Make a Difference?

Why You Need to Learn Weaving in Electric Welding

Stacking dimes Vs Stringers, which is stronger? (part 2)

Flashback to Stringers vs Waves #shorts: https://www.youtube.com/watch?v=-W1E0bxjcEc

Stringer beads and weaves. #stickwelding #welder #smaw #e7018 #welding #weldingschool #weldernation

3F 2 Pass Vertical MIG Weld

TWO Different Weaving Patterns 🔥 #shorts #welder #welding

How to Stack Your Beads When Stick Welding

The key to weaving a nice cap pass is staying in the bevels #welding #shorts

Stick Welding Basics - How to Run Straight Consistent Beads

Understanding Fiberglass Types - Different Weaves, Weights and Uses - Basics of Fiberglass Fabric

Комментарии

0:29:25

0:29:25

0:13:11

0:13:11

0:07:37

0:07:37

0:17:17

0:17:17

0:00:57

0:00:57

0:00:26

0:00:26

0:13:25

0:13:25

0:05:43

0:05:43

0:00:19

0:00:19

0:05:48

0:05:48

0:10:25

0:10:25

0:00:41

0:00:41

0:15:43

0:15:43

0:03:16

0:03:16

0:06:50

0:06:50

0:59:17

0:59:17

0:00:12

0:00:12

0:01:01

0:01:01

0:03:16

0:03:16

0:00:07

0:00:07

0:16:32

0:16:32

0:00:23

0:00:23

0:13:50

0:13:50

0:13:02

0:13:02