filmov

tv

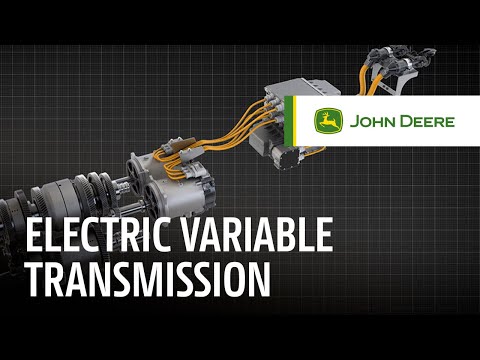

+Gain Ground with Electric Variable Transmission | John Deere Tractors

Показать описание

The all-new Electric Variable Transmission takes everything you love about our Infinitely Variable Transmission and provides exceptionally smooth operation with less operating noise.

0:00 +Gain Ground with Electric Variable Transmission

0:31 Stepless Transmission Design

0:47 Electric Motors

0:58 Electric Power Generation

1:24 Talk to Your John Deere Dealer

--- Follow Us ---

--- More from John Deere ---

#JohnDeere #ElectricVariableTransmission #Tractor #8R410 #8RT410 #8RX410 #GainGround

0:00 +Gain Ground with Electric Variable Transmission

0:31 Stepless Transmission Design

0:47 Electric Motors

0:58 Electric Power Generation

1:24 Talk to Your John Deere Dealer

--- Follow Us ---

--- More from John Deere ---

#JohnDeere #ElectricVariableTransmission #Tractor #8R410 #8RT410 #8RX410 #GainGround

+Gain Ground with Electric Variable Transmission | John Deere Tractors

+Gain Ground with See & Spray™ Ultimate | John Deere Precision Ag

+Gain Ground with StarFire™ 7000 Receiver | John Deere Precision Ag

John Deere 8RX EVT Electric Variable Transmission

Stepless goes electrical: eAutoPowr TRANSMISSION

Differential Amplifier with Variable Gain and feedback loop

22 Low Noise and Variable Gain Amplifiers

Building a Photodiode Amplifier with Variable Gain

120.1 Potential Dividers Level Up! | A2 Electronics | Cambridge A Level Physics

Designing a 3 wire load cell amplifier with variable gain and offset

39 The Capacitor in Electric Circuits

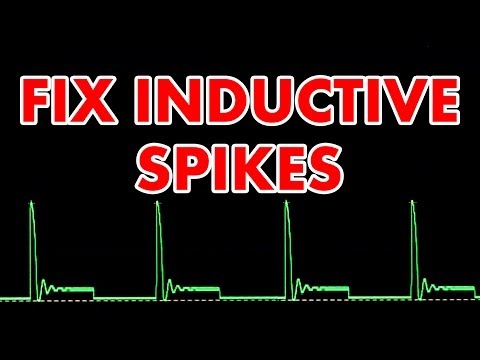

Inductive spiking, and how to fix it!

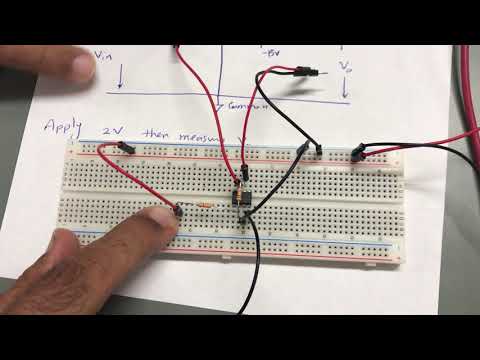

Lab 5a Operational Amplifier inverting amplifier

Solution, Fundamentals of electrical circuits sadiku, exercise 3.31

ADDING A SWITCH TO YOUR VARIABLE CONTROLLER

Instrument Basics: Bench Power Supplies - Workbench Wednesdays

Agritechnica: Electric drive implement power gains momentum

Design and Testing of Voltage Controlled Variable Gain Amplifier

Electronics on the floor: Fun with variable resistors / potentiometers

How to use a BreadBoard - Electronics Basics 10

IECON2016-Variable Gain Iterative Learning Contouring Control for Feed Drive Systems

Learning variable impedance control

#agco #cvt #transmission #inovative #agriculture #tractor #thebest #masseyferguson #massey #8s

John Deere Direct Drive gearbox “opening”

Комментарии

0:01:43

0:01:43

0:10:19

0:10:19

0:03:03

0:03:03

0:03:09

0:03:09

0:01:40

0:01:40

0:08:33

0:08:33

0:12:42

0:12:42

0:07:27

0:07:27

0:22:17

0:22:17

0:15:42

0:15:42

0:10:44

0:10:44

0:04:54

0:04:54

0:11:18

0:11:18

0:16:32

0:16:32

0:23:37

0:23:37

0:09:16

0:09:16

0:03:43

0:03:43

0:53:37

0:53:37

0:10:34

0:10:34

0:07:22

0:07:22

0:03:01

0:03:01

0:00:49

0:00:49

0:00:31

0:00:31

0:00:18

0:00:18