filmov

tv

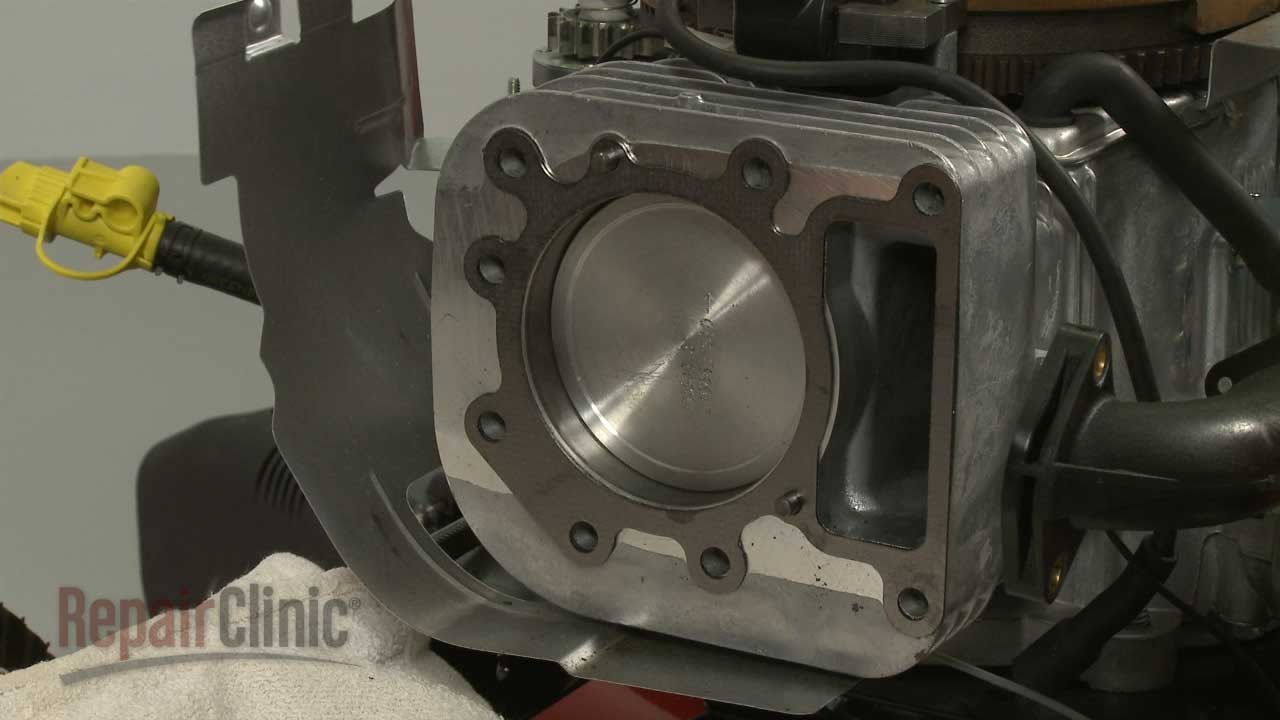

Briggs & Stratton Riding Mower Engine Head Gasket #794114

Показать описание

This video provides step-by-step instructions for replacing the head gasket on Briggs and Stratton small engines, commonly found in Toro riding lawn mowers. The most common reason for replacing the gasket is when making repairs to the engine.

All of the information in this gasket replacement video is applicable to the following brands: Briggs & Stratton, Toro

Tools used: 1/4” socket or nut driver, 3/8” socket or nut driver, 5/8” socket or spark plug wrench, 1/4” hex bit, large flat-head screwdriver, T20 Torx bit screwdriver, torque wrench, gauge

Model displayed: Briggs & Stratton riding mower engine 331977/0010-G1

Connect With Us!

Don't forget to like and comment on this video, and subscribe to our channel!

All of the information in this gasket replacement video is applicable to the following brands: Briggs & Stratton, Toro

Tools used: 1/4” socket or nut driver, 3/8” socket or nut driver, 5/8” socket or spark plug wrench, 1/4” hex bit, large flat-head screwdriver, T20 Torx bit screwdriver, torque wrench, gauge

Model displayed: Briggs & Stratton riding mower engine 331977/0010-G1

Connect With Us!

Don't forget to like and comment on this video, and subscribe to our channel!

Briggs & Stratton TURBO first ride

Craftsman YT3000 - Working on the Briggs & Stratton 21HP Platinum

Unboxing A New Briggs & Stratton Engine For A John Deere Lawn Tractor #shorts

NEW BRIGGS STRATTON ENGINE TWO CYLINDER for Lawnmower Tractor #shorts

Craftsman 46' Auto 19HP Briggs & Stratton Turn Tight® Riding Mower

How To Change an Air Filter by Briggs & Stratton®

Snapper 12.5hp Briggs and Stratton riding mower issue?

John Deere OEM 17.5 hp Briggs & Stratton engine.

Top 5 Best Riding Lawn Mower in 2024

Briggs and Stratton Fuel Pump Replacement - $6 QUICK FIX!!!

Briggs and Stratton EX 1900 fuel system

Murray Select Garden Tractor 13.5 HP Briggs & Stratton. #mower #tractor #briggsandstratton brigg...

Oil Change- Briggs & Stratton 12.5hp Mower

Briggs Stratton 15.5 hp Murray Lawn Tractor

Oil Change Intek B&S Briggs and Stratton OHV 21.0 HP Mower Troy Bilt 809 Riding Tractor 60oz

How to Use Your Murray® MT100 or MT200 Lawn Tractor

First Start in 20 Years - MTD Riding Mower w/Briggs IC Engine

24 hp Briggs & Stratton Intek V-Twin

Jump start Briggs & Stratton riding mower

Briggs & Stratton Powerbuilt Series 31R976-0016-G1

Best Oil For Lawn Mower Reviews [Top 5 Lawn Mower Oil Review]

Lawn mowers to avoid!

Mower Engine Surging? Idling poorly? Running rough?

THE BIG SHOP SECRET! How to fix your OEM Briggs Nikki carburetor with an OEM carb kit for ONLY $18!

Комментарии

0:01:48

0:01:48

0:26:12

0:26:12

0:00:51

0:00:51

0:00:09

0:00:09

0:01:14

0:01:14

0:00:21

0:00:21

0:01:32

0:01:32

0:00:58

0:00:58

0:07:16

0:07:16

0:06:47

0:06:47

0:00:51

0:00:51

0:01:01

0:01:01

0:05:05

0:05:05

0:00:16

0:00:16

0:06:25

0:06:25

0:01:20

0:01:20

1:33:18

1:33:18

0:00:28

0:00:28

0:03:08

0:03:08

0:00:26

0:00:26

0:05:51

0:05:51

0:10:40

0:10:40

0:03:33

0:03:33

0:09:31

0:09:31