filmov

tv

Breaking Good

Показать описание

If you Google for "aircraft cylinder break-in" you'll get about 488,000 hits. Each manufacturer (Continental & Lycoming) has a Service Bulletin about it, most PMA cylinder makers (ECi, Superior) have a procedure, and many of the custom overhaul chops (Pann Yann, Victor, RAM) have one. Some of the type clubs have one - even Shell Oil offers advice. That's a lot of reading - it's probably smarter to just read watch Mike Busch's webinar.

Breaking Good | Michael Franzese | EP 302

breaking good

Breaking Bad - But no one is careful - Part 1

Hank prevents Breaking Bad entirely

Breaking Bad - Wire

Tuco uses the Infinity Stones in the MOST efficient way

Breaking Bad Jr.

Breaking Kitchen - Episode 1

Breaking Good @ New Life Petrolia

Fixing Good | Official Teaser Trailer

Breaking Bad - But no one is careful - Part 2

Breaking bad if Skyler didn't exist.

Gus Fring Survives

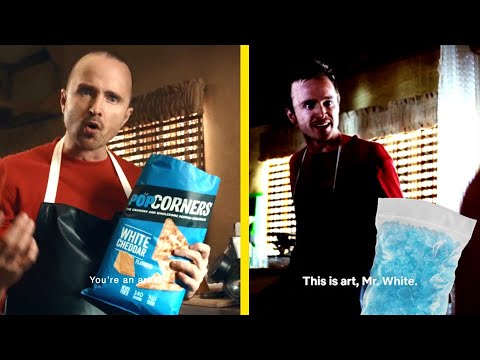

SNACKS, YO! #Popcornersbreakinggood #breakingbad #walterwhite #bryancranston #aaronpaul

Walter White in Mario Kart Wii

Why Breaking Bad Became A Meme

breaking good ep 3 (live action)

How Breaking Bad Pulled Off An Impossibly Perfect Finale

Super Bowl Ad vs Breaking Bad Real

If Breaking Bad Was A Nickelodeon Cartoon

Entire Breaking Bad Series in 3 Minutes

Breaking Bad Universe Ranked | #Shorts

𝑰 𝑾𝒂𝒔 𝑮𝒐𝒐𝒅 𝑨𝒕 𝑰𝒕

Breaking Bad Cast Then vs Now | #Shorts

Комментарии

1:45:10

1:45:10

0:00:27

0:00:27

0:02:54

0:02:54

0:01:04

0:01:04

0:00:24

0:00:24

0:00:48

0:00:48

0:06:40

0:06:40

0:01:59

0:01:59

1:33:35

1:33:35

0:00:34

0:00:34

0:03:57

0:03:57

0:00:22

0:00:22

0:00:33

0:00:33

0:00:31

0:00:31

0:00:31

0:00:31

0:10:14

0:10:14

0:00:26

0:00:26

0:09:20

0:09:20

0:00:54

0:00:54

0:00:54

0:00:54

0:03:29

0:03:29

0:00:51

0:00:51

0:06:43

0:06:43

0:00:38

0:00:38