filmov

tv

Processing a Part at an IMPOSSIBLE Angle #shorts

Показать описание

Processing a Part at an IMPOSSIBLE Angle

Trevor uses the Trumpf TruMark Station 5000 to laser engrave a part. The part is sitting at a 45% angle, showing that the laser can easily stay in focus even when the part is not sitting flat.

#shorts #CNC #Machining #Machinist

Trevor uses the Trumpf TruMark Station 5000 to laser engrave a part. The part is sitting at a 45% angle, showing that the laser can easily stay in focus even when the part is not sitting flat.

#shorts #CNC #Machining #Machinist

Getting Down to Basics - Payments Processing (Part 1)

Morcheeba - Part Of The Process - Big Calm (1998)

Part of the Process

Chapter 21,17 - Transaction Processing - Part 1

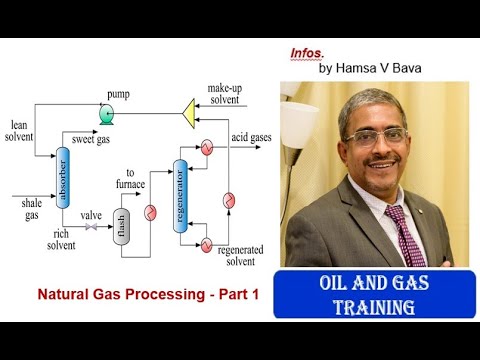

Natural Gas Processing - Part 1

Part of the Process

Mistakes Are Part Of The Process. 🤍

Process of Making Ball Bearings. A Mechanical Parts Manufacturing Factory in Korea.

Chapter 3 (Part-3) || Central Processing Unit and Instructions || A6-R5.1 || A Level || GyanXp

In-Process Part Measurement; Probing in 5 Simple Steps - Haas Automation Tip of the Day

Coding Challenge #7: Solar System in Processing - Part 1 (2D)

Q&A #7.1: Comparing p5.js and Processing - Part 1

Chapter 21,17-Transaction Processing - Part 4

Lathe Machining for Aerospace Parts Precision Required #cnc #process

Derm Explains Aging Process Part 1 #shorts

Chest bag production process and size chart Sewing Tutorial Part 83

Can FPGAs compete with GPUs in Image Processing? (Part 1)

Confirmation of your fix. Make sure it’s part of your repair process

Vario 150 motorbike dismantling process part 2? #vario #cvt

#Accessories processing #Parts processing #Hardware processing #Processing center

Coding Challenge #9: Solar System in Processing - Part 3 (3D textures)

Leica Infinity – UAV Processing Part 3 - Create Dense Point Cloud, DSM and Orthophoto

Leica Infinity – UAV Processing Part 2 - Add GCPs and update orientation

Q&A #7.2: Comparing p5.js and Processing - Part 2

Комментарии

0:09:57

0:09:57

0:04:25

0:04:25

0:04:26

0:04:26

1:24:05

1:24:05

0:15:34

0:15:34

0:04:26

0:04:26

0:00:55

0:00:55

0:13:40

0:13:40

0:46:07

0:46:07

0:07:29

0:07:29

0:30:47

0:30:47

0:16:04

0:16:04

0:39:07

0:39:07

0:00:23

0:00:23

0:00:43

0:00:43

0:01:00

0:01:00

0:07:56

0:07:56

0:00:56

0:00:56

0:00:16

0:00:16

0:00:16

0:00:16

0:12:05

0:12:05

0:04:04

0:04:04

0:02:52

0:02:52

0:22:36

0:22:36