filmov

tv

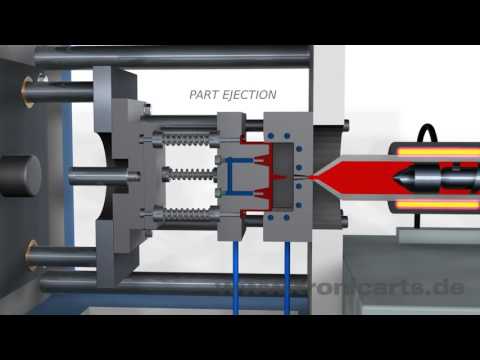

How to do plastic injection quality well? #design #injection #plastic #machines #production

Показать описание

How to do plastic injection quality well?

Here are some essential steps to ensure good plastic injection quality:

1. Design Considerations:

- Part Design: Design parts with moldability in mind. Consider uniform wall thickness, proper draft angles, and avoid sharp corners.

- Material Selection: Choose the appropriate plastic material for your application, considering factors such as strength, temperature resistance, and cost.

2. Tool Design:

- Work with experienced tool designers to create molds that are precise, durable, and easy to maintain.

- Use high-quality materials for the mold to ensure longevity and dimensional stability.

3. Process Optimization:

- Develop a robust injection molding process with parameters such as temperature, pressure, and injection speed optimized for the specific material and part geometry.

- Conduct a thorough process validation to identify and eliminate potential issues.

4. Quality Control:

- Implement strict quality control measures at every stage of production.

- Regularly inspect and maintain the mold to prevent defects and extend its lifespan.

5. Raw Material Quality:

- Source high-quality raw materials to ensure consistent and reliable production.

- Establish good relationships with material suppliers to maintain consistency.

6. Injection Molding Machine Maintenance:

- Regularly inspect and maintain injection molding machines to prevent malfunctions and ensure consistent production.

- Calibrate machines regularly to maintain accuracy.

7. Training and Skill Development:

- Provide comprehensive training for machine operators and technicians to ensure they understand the importance of each parameter and how it affects product quality.

- Encourage continuous learning and skill development.

8. Process Monitoring:

- Use monitoring and control systems to track key parameters during the injection molding process.

- Implement statistical process control (SPC) to identify and correct variations before they result in defects.

9. Quality Assurance Procedures:

- Develop and implement quality assurance procedures, including regular inspections and testing of finished products.

- Establish a system for traceability to quickly identify and rectify any quality issues.

10. Customer Feedback and Continuous Improvement:

- Act on customer feedback to make necessary improvements.

- Foster a culture of continuous improvement, where all team members actively contribute to enhancing processes and product quality.

By paying attention to these factors and continuously improving processes, can enhance the quality of plastic injection molding production. Regular reviews and adjustments based on performance data will contribute to long-term success in maintaining high standards. #plastic #plasticinjection #injection #sustainable #ecofriendly #mold #molddesign #moldmaking #innovation #engineering #industrialdesign #machine

Here are some essential steps to ensure good plastic injection quality:

1. Design Considerations:

- Part Design: Design parts with moldability in mind. Consider uniform wall thickness, proper draft angles, and avoid sharp corners.

- Material Selection: Choose the appropriate plastic material for your application, considering factors such as strength, temperature resistance, and cost.

2. Tool Design:

- Work with experienced tool designers to create molds that are precise, durable, and easy to maintain.

- Use high-quality materials for the mold to ensure longevity and dimensional stability.

3. Process Optimization:

- Develop a robust injection molding process with parameters such as temperature, pressure, and injection speed optimized for the specific material and part geometry.

- Conduct a thorough process validation to identify and eliminate potential issues.

4. Quality Control:

- Implement strict quality control measures at every stage of production.

- Regularly inspect and maintain the mold to prevent defects and extend its lifespan.

5. Raw Material Quality:

- Source high-quality raw materials to ensure consistent and reliable production.

- Establish good relationships with material suppliers to maintain consistency.

6. Injection Molding Machine Maintenance:

- Regularly inspect and maintain injection molding machines to prevent malfunctions and ensure consistent production.

- Calibrate machines regularly to maintain accuracy.

7. Training and Skill Development:

- Provide comprehensive training for machine operators and technicians to ensure they understand the importance of each parameter and how it affects product quality.

- Encourage continuous learning and skill development.

8. Process Monitoring:

- Use monitoring and control systems to track key parameters during the injection molding process.

- Implement statistical process control (SPC) to identify and correct variations before they result in defects.

9. Quality Assurance Procedures:

- Develop and implement quality assurance procedures, including regular inspections and testing of finished products.

- Establish a system for traceability to quickly identify and rectify any quality issues.

10. Customer Feedback and Continuous Improvement:

- Act on customer feedback to make necessary improvements.

- Foster a culture of continuous improvement, where all team members actively contribute to enhancing processes and product quality.

By paying attention to these factors and continuously improving processes, can enhance the quality of plastic injection molding production. Regular reviews and adjustments based on performance data will contribute to long-term success in maintaining high standards. #plastic #plasticinjection #injection #sustainable #ecofriendly #mold #molddesign #moldmaking #innovation #engineering #industrialdesign #machine

0:00:27

0:00:27

0:05:21

0:05:21

0:09:37

0:09:37

0:02:59

0:02:59

0:00:26

0:00:26

0:02:41

0:02:41

0:00:22

0:00:22

0:03:19

0:03:19

1:00:24

1:00:24

0:03:51

0:03:51

0:35:41

0:35:41

0:08:20

0:08:20

0:00:14

0:00:14

0:01:35

0:01:35

0:01:46

0:01:46

0:00:16

0:00:16

0:00:30

0:00:30

0:10:42

0:10:42

0:00:38

0:00:38

0:14:19

0:14:19

0:07:57

0:07:57

0:16:46

0:16:46

0:13:55

0:13:55

0:00:24

0:00:24