filmov

tv

Enough is Enough! The Line Has Been Crossed!

Показать описание

In today's furious rant, I share my frustrations with the Milwaukee Fuel M18 framing saw. In my experience, when set to its maximum depth, it doesn't clear a speed square, which is a crucial tool for making precise cuts. Compared to the West Coast-style saws like the Skil Mag 77 or my DeWalt Flexvolt, which easily clear a speed square and have the blade on the left for better visibility, this is quite disappointing.

I'll also address some of the feedback I've received, suggesting I use my other hand (even though I'm right-handed) or avoid setting the saw so deep. These suggestions, in my opinion, miss the practical reality of needing to use a speed square for deep cuts. Join me as I share my thoughts and frustrations. Let's discuss! Many of our videos are comedic & satirical & not intended to cultivate antisocial or unlawful behavior.

Thank you for supporting our Channel through the below affiliate links. No price increase for you but we may receive compensation.

#proho #wranglerstar

I'll also address some of the feedback I've received, suggesting I use my other hand (even though I'm right-handed) or avoid setting the saw so deep. These suggestions, in my opinion, miss the practical reality of needing to use a speed square for deep cuts. Join me as I share my thoughts and frustrations. Let's discuss! Many of our videos are comedic & satirical & not intended to cultivate antisocial or unlawful behavior.

Thank you for supporting our Channel through the below affiliate links. No price increase for you but we may receive compensation.

#proho #wranglerstar

Enough Is Enough

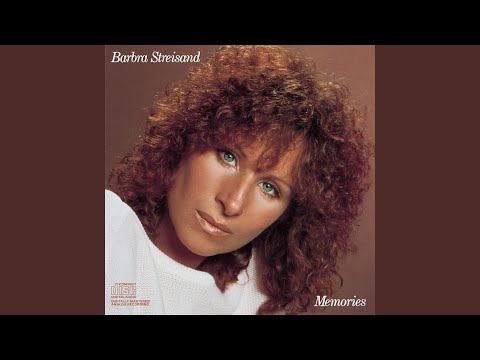

No More Tears (Enough Is Enough)

Fallout 4 OST - Enough Is Enough

ENOUGH IS ENOUGH - Best Motivational Speech Video (Featuring Eddie 'Truck' Gordon)

Professor Has HAD ENOUGH Of “Woke” Double Standards

Enough Is Enough

Tamia Dance “Can’t Get Enough” #linedance #enough

'Food Over Everything: When Being Cute Isn’t Enough! 🤳🍗😂 #funny #shorts'

NATURE SET - Enough Is Enough [Official]

MUSLIM WIVES CROSSING LINES - ENOUGH IS ENOUGH!!

THIS TOWN AINT BIG ENOUGH FOR THE TWO OF US #shorts

'Never Enough' Singer Loren Allred: Then and Now! | Got Talent Global

Eno Barony - Enough Is Enough ft. Wendy Shay ( Official Video)

Enough Is Enough

Gary Barlow - Enough Is Enough (Lyrics)

Line - 'Almost Is Never Enough' | Knockouts | The Voice van Vlaanderen | VTM

Christ is enough | His Life City Church 2022 #InChristAlone #HislifeChurch

I have no enemies.. #shorts #anime #edit #animeedit #berserk #happy #noenemies

Vietnam Had Enough of China - Get Out NOW!

My son learned the Tamia Hustle - Can’t Get Enough of you Line Dance!! And it went “Viral”!

White Lies - Is My Love Enough? (Official Unofficial Video)

Never Enough (Official Music Video) - Loren Allred

ENOUGH [2002] - Official Trailer (HD)

April Wine - Enough is Enough

Комментарии

0:00:20

0:00:20

0:04:43

0:04:43

0:02:19

0:02:19

0:10:31

0:10:31

0:18:33

0:18:33

0:06:26

0:06:26

0:00:19

0:00:19

0:00:06

0:00:06

0:03:32

0:03:32

0:16:25

0:16:25

0:00:08

0:00:08

0:17:12

0:17:12

0:03:22

0:03:22

0:04:39

0:04:39

0:04:04

0:04:04

0:01:41

0:01:41

0:06:31

0:06:31

0:00:22

0:00:22

0:17:37

0:17:37

0:00:16

0:00:16

0:05:56

0:05:56

0:03:49

0:03:49

![ENOUGH [2002] -](https://i.ytimg.com/vi/0tahxDOAzT4/hqdefault.jpg) 0:02:22

0:02:22

0:04:06

0:04:06