filmov

tv

How To Make A Regulator Pin Adjusting Tool

Показать описание

In this video I show you how to make a tool to safely open the regulator pins when you are adjusting and regulating a watch movement and explain why you would want to do so. Enjoy.

*****************************************************************************

✨✨ Get Your Copy of my eBook, The Secrets for Adjusting Watch Rates ✨✨

✨✨Watchmaking Courses and Training ✨✨

**************************************************************************************************

🚀 Don't Miss Out: Sign up for the "It's About Time" Monthly Newsletter

DISCLOSURE: I often review or link to products & services I regularly use and think you might find helpful. Wherever possible I use referral links, which means if you click one of the links in this video or description and make a purchase we may receive a small commission or other compensation.

IN THIS VIDEO

MY MICROSCOPE SET-UP

** FULL LIST OF TOOLS & SUPPLIES I USE **

*****************************************************************************

✨✨ Get Your Copy of my eBook, The Secrets for Adjusting Watch Rates ✨✨

✨✨Watchmaking Courses and Training ✨✨

**************************************************************************************************

🚀 Don't Miss Out: Sign up for the "It's About Time" Monthly Newsletter

DISCLOSURE: I often review or link to products & services I regularly use and think you might find helpful. Wherever possible I use referral links, which means if you click one of the links in this video or description and make a purchase we may receive a small commission or other compensation.

IN THIS VIDEO

MY MICROSCOPE SET-UP

** FULL LIST OF TOOLS & SUPPLIES I USE **

How to make voltage regulator at home

5V Regulator design tutorial - How it works, how to design PCB altium

How to Make Adjustable Voltage Regulator / Voltage Converter

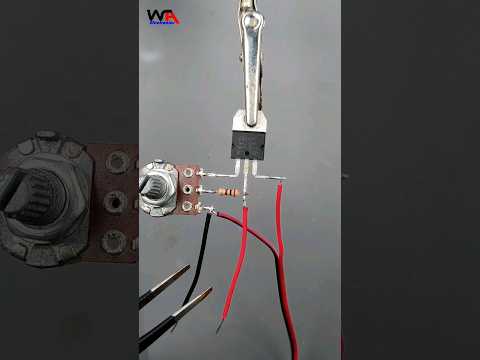

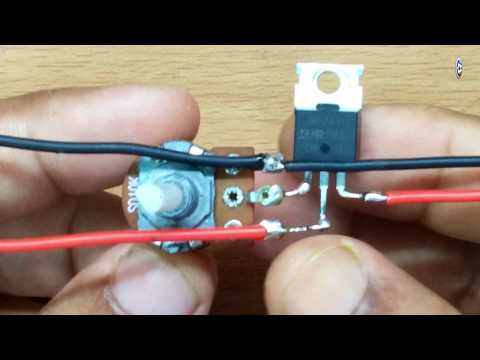

Mosfet Powerful Voltage Regulator IRFZ44 Mosfet #shorts #shortfeed #diy

DIY Zener Diode - Make Your Voltage Regulator with Diodes!

1 to 12v Adjustable Voltage Regulator Circuit #lm317 #voltageregulator #diyelectronics

DIY 220v AC regulator circuit diagram, AC voltage adjustable controller

Voltage regulator circuit | 0 to 60V variable power supply #voltageregulator

AC Voltage Regulator How to Make At Home || Fan Regulator@crazymrare

Adjustable Voltage Regulator Using 2N3055 | 0-48V 15A

Diy ac voltage⚡️ regulator | BT 136 Triac 220v ac voltage regulator circuit #shorts

3V DC to 400V DC adjustable voltage regulator circuit #shorts #diy

Diy Project || voltage regulator with 7805

How to Make 12 Volt Regulator Using LM7812 #shortsvideo #shorts #regulator

12V to 5V Converter Circuit | 7805 Voltage Regulator #electronic

How To Make Adjustable Voltage Regulator Using 7805

Voltage regulator tutorial & USB gadget charger circuit

12v to 5v converter 7805 voltage regulator

0 - 220V Variable power supply | Voltage regulator circuit | Fan speed controller | Dimmer

Adjustable Voltage Regulator Using Mosfet

how to make voltage regulator with mosfet

DIY AC Regulator circuit Diagram tutorial, Smoothly working 2000 watt Regulator

How a gas regulator works

Voltage Regulator Circuit #voltageregulator #shorts #diy

Комментарии

0:00:16

0:00:16

0:16:02

0:16:02

0:02:34

0:02:34

0:00:53

0:00:53

0:00:33

0:00:33

0:00:34

0:00:34

0:05:22

0:05:22

0:00:13

0:00:13

0:05:37

0:05:37

0:00:58

0:00:58

0:00:28

0:00:28

0:00:39

0:00:39

0:00:36

0:00:36

0:00:34

0:00:34

0:00:36

0:00:36

0:02:34

0:02:34

0:06:28

0:06:28

0:00:26

0:00:26

0:00:16

0:00:16

0:01:00

0:01:00

0:05:15

0:05:15

0:03:41

0:03:41

0:04:54

0:04:54

0:00:31

0:00:31