filmov

tv

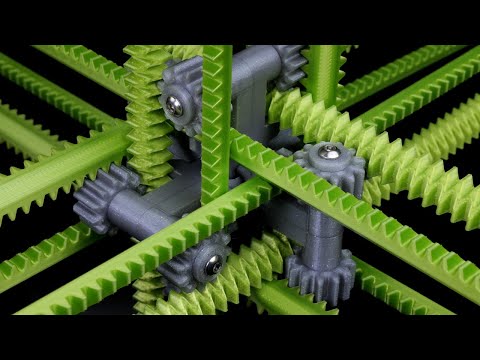

Six axis racks

Показать описание

A kinetic sculpture in which 12 sticks with 24 racks interact with 12 gears.

Six axis racks

EP E610P 10L six-axis agricultural rack farmland spraying

Hwashi Six Axis Industrial MIG Welding Robot for Storage Wire Shelf Corner,Shelf welding robot

GSK RH06A3 series welding industrial robot six axis handling robot

Used KUKA Robot KR210, KRC2 EDi05 Controller, 6 Axis 2700mm Reach 210 Kg Payload, With All Spares

f05114 six-axis rack Fuss i6 remote apm flight control installation

china's best CNC Motorized XYZ Gantry Robot System Rack manufacturer

Six thick steel plate shredders # Double axis shredder # Car rack shredder

XZ-Axis Manual Stage- Rack and Pinion Dovetail Translation Stages

6-axis industrial Robotic Deburring Applications

#Borunte six axis robot- full automation line~

Industrial 6 Axis Welding Robot Manufacturer Supplier in China

Racks Welding Processes with Robot's Robotic Welding Arm #production #machine #qualitymanagemen...

6 axis arm robot for weld IRB 4600 industrial robot arm2

robotics 6 axis

6 Axis Industrial Robot Arm Stainless Steel Iron Aluminium MIG Welding Robot

DIY Sorinex Hurricane with Six Axis Movement #lego #gym #shorts

Rack and pinion Arrangement of gears

Six Axis Industrial Robotic Welding Machine Steel Structure

Gear rack and parallelogram mechanism - Mechanical Animation #mechanics #animation

[SteviS Laser] Industrial 6-axis welding robot with positioner, for steel tee pipe fitting producing

6-axis Robotic Automatic Spray Painting Robot for Automotive Parts Painting Line

Basic Mechanisms: Rack and Pinion

Solution to air fryer pot with direct entry material rack, 4 axis and 5 axis swing arm Qinfeng robot

Комментарии

0:10:17

0:10:17

0:00:41

0:00:41

0:00:12

0:00:12

0:00:11

0:00:11

0:00:17

0:00:17

0:08:54

0:08:54

0:00:18

0:00:18

0:00:30

0:00:30

0:00:50

0:00:50

0:00:36

0:00:36

0:00:11

0:00:11

0:00:36

0:00:36

0:00:33

0:00:33

0:00:12

0:00:12

0:01:01

0:01:01

0:00:11

0:00:11

0:00:19

0:00:19

0:00:16

0:00:16

0:00:12

0:00:12

0:01:00

0:01:00

![[SteviS Laser] Industrial](https://i.ytimg.com/vi/20h_muUWmh0/hqdefault.jpg) 0:00:22

0:00:22

0:00:12

0:00:12

0:00:35

0:00:35

0:01:41

0:01:41