filmov

tv

This monster made my homemade jet engine 2.5x more powerful.

Показать описание

Today we're building the new centrifugal Supercharger that I designed for my homemade electric jet engine. The compressor worked really well and I hope you guys enjoyed the build!

My Parts List:

#homemade #jetengine #3dprinting

My Parts List:

#homemade #jetengine #3dprinting

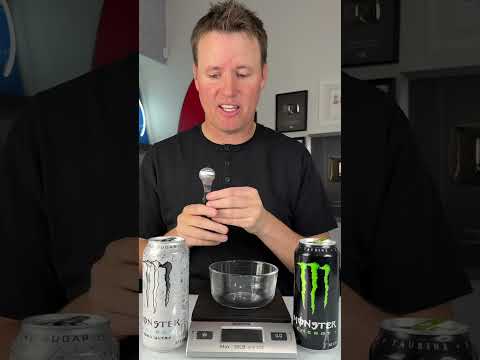

What's inside Monster Energy Drink?

Monster makes my day better 👻😃 #shorts

🍺Hago JARRA de Monster Energy con LATA 🍺I Make Monster Energy JAR with CAN | Powerful Creations...

What your favorite monster flavor says about you

You Will Never Drink MONSTER Energy Again After Watching This Video

Self-made Zinogre Cosplay from Monster Hunter!

Street Legal Monster!

Compact Light Duty Wood Storage #diy #carpentry

Redbull vs Monster Energy 🐂👹

Making the Terrifying Monster House Cake #shorts #cake #spooky #food #chocolate

Using digilegs stilts in my owl monster costume.

Cleo De Nile - Monster High 💎#monsterhighmakeup #cleodenile #monsterhigh

I built Monster Hunter Bone Blades out of foam! #cosplay #diycrafts

The Inside Of Kit Kats Are NOT What You Think 😯

Making Creepy House From Monster House Animated Movie

MONSTER MUD TUTORIAL - Turn ANYTHING into stone!

Rainforest Island ANIMATED - The Finale - The Monster Explorers

Surprising my little sister with homemade crumbl cookies!!! 🍪

I've created a beautiful monster. All fear and respect loooooong turkey! 🦃

DIY monster face mask #emo #metal #diy #goth #punk #monster

Cookie Monster Cookies!?!

I made a Mini Monster House

I made my own Monster High Dolls! #draculaura #monsterhigh #custom #doll #bjd #art #artist #mattel

Monster Truck Suspension Test

Комментарии

0:00:35

0:00:35

0:00:58

0:00:58

0:00:54

0:00:54

0:00:53

0:00:53

0:02:44

0:02:44

0:01:00

0:01:00

0:00:10

0:00:10

0:00:59

0:00:59

0:00:37

0:00:37

0:00:48

0:00:48

0:00:49

0:00:49

0:00:46

0:00:46

0:01:01

0:01:01

0:00:22

0:00:22

0:09:38

0:09:38

0:12:22

0:12:22

0:02:10

0:02:10

0:01:01

0:01:01

0:00:10

0:00:10

0:00:19

0:00:19

0:00:31

0:00:31

0:10:10

0:10:10

0:00:08

0:00:08

0:00:10

0:00:10