filmov

tv

How Europe's biggest 3D-printed building is being constructed | DW News

Показать описание

In Heidelberg, Europe's biggest 3D-printed building is under construction: using additive concrete. The pros: fewer workers are needed and the procedure is supposed to be more climate-friendly. Are 3D printers the construction workers of the future?

Follow DW on social media:

#housing #3dprinting

Follow DW on social media:

#housing #3dprinting

How Concrete Homes Are Built With A 3D Printer | Insider Art

Timelapse / Zeitraffer Europe's largest 3D-printed apartment building

Only 140 hours needed to put together ‘Europe’s largest 3D-printed building’

Europe's biggest concrete 3D printer creates the home of tomorrow

Europe's biggest 3D-printed apartments being built in Germany

3D Printed Concrete House, Printed in 48 hours

Time-lapse of the World's Largest 3D Printed Boat

3D PRINTING | PERI 3D Construction Printing: Largest printed apartment building in Europe (EN)

3d Printed Sock Knitting Machine How to Start

World's largest 3D-printed building constructed in Dubai

I VISITED THE WORLDS BIGGEST 3D PRINTED BUILDING!!!

Why This 3D-Printed House Will Change The World

The First 100% Bio-Based 3D-Printed Home | Printed on the World's Largest 3D Printer

Eco-sustainable 3D printed house - Tecla

Inside A 3D Printed House You'll ACTUALLY Want To Live In

Europes largest 3D prtinted house!

Largest 3D printed building in the world 🌎 (Apis Cor)

The Most Innovative 3D Printed House In The World [Mense-Korte]

Watch robots build houses at incredible speed. 3D printing meets AI.

How construction 3D printing is changing our world

3D Printed Buildings

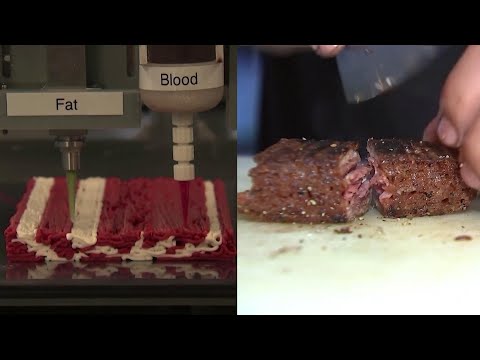

This 3D-Printed Meat Cuts Like Steak

The COST Of A 3D PRINTED HOUSE In 2021

The Truth About 3D Printed Homes

Комментарии

0:05:33

0:05:33

0:01:00

0:01:00

0:01:07

0:01:07

0:03:00

0:03:00

0:01:27

0:01:27

0:03:28

0:03:28

0:00:37

0:00:37

0:00:59

0:00:59

0:14:56

0:14:56

0:01:09

0:01:09

0:08:29

0:08:29

0:09:34

0:09:34

0:04:13

0:04:13

0:01:57

0:01:57

0:09:37

0:09:37

0:00:47

0:00:47

0:08:16

0:08:16

0:12:48

0:12:48

0:13:35

0:13:35

0:09:39

0:09:39

0:06:05

0:06:05

0:01:22

0:01:22

0:07:19

0:07:19

0:10:56

0:10:56