filmov

tv

End Mills, The Nitty-Gritty: Intro

Показать описание

Hello everyone, welcome to At-Man Unlimited. End Mills, where the metal hits the work piece. They make the chips actually fly. The final link to making good parts.

In this series we will explore the different aspects of end mills. Let’s start with HSS or Carbide and why you would choose one over another.

Please keep in mind throughout this series that this is for entertainment only. While I try my best to have the facts straight I am not a tool designer or supplier. Some items in here are my opinion and should be taken as such. What works for me may not be right for you.

If you would like to support the channel please visit our Patreon page

In this series we will explore the different aspects of end mills. Let’s start with HSS or Carbide and why you would choose one over another.

Please keep in mind throughout this series that this is for entertainment only. While I try my best to have the facts straight I am not a tool designer or supplier. Some items in here are my opinion and should be taken as such. What works for me may not be right for you.

If you would like to support the channel please visit our Patreon page

End Mills, The Nitty-Gritty: Intro

End Mills, The Nitty-Gritty: Cutter Engagement and 'Chatter'

End Mills, The Nitty-Gritty: Face Mills and Inserts

End Mills, The Nitty-Gritty: Flutes and Helix Angles

End Mills, The Nitty-Gritty: Cutter Geometry

Endmill Fundamentals

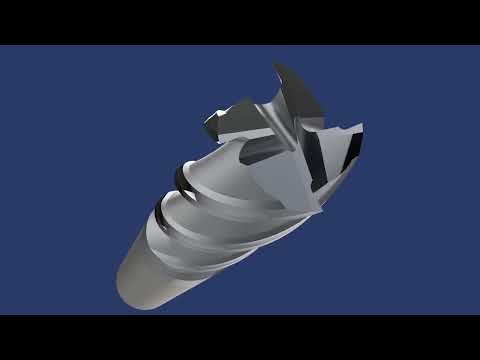

ANATOMY OF AN ENDMILL

Endmill chatter at 20,000 Frames-per-Second

ISCAR TECH TALK - SOLID CARBIDE & MULTI-MASTER ENDMILL

Tormach Explains the Science Behind an End Mill

Integrated 3D Simulation for endmill grinding

End Mill Comparison Guide

Helix Angles: In The Loupe TV Ep.4

Single Flute end mill at 15,000 FPS

Proper Care & handling of End Mills - Grainger Ask the Experts

YG-1 Cutting Tools | [Milling] Only One_End Mills_Coated PM60 End Mill

At-Man Unlimited Introduction

Shop Talk 6: Center Cutting Endmills, Indicator Mounting, Noga Mini-Cool, Floor Mats

How to mill and drill metal

Take on the tough materials with new long-lasting JS750 end mills | Seco Tools

END MILL RPM AND FEED CALCULATION VIDEO- 03

Intro to CNC - Part 2: CNC Hardware Basics

LOOK at ELVIS' HANDS as he LEAVES STAGE FOR THE LAST TIME EVER...it's a KARATE Signal #sho...

SilverLine - Solid carbide end mills

Комментарии

0:13:42

0:13:42

0:17:34

0:17:34

0:18:31

0:18:31

0:23:58

0:23:58

0:19:04

0:19:04

0:13:29

0:13:29

0:02:20

0:02:20

0:09:11

0:09:11

0:01:49

0:01:49

0:03:09

0:03:09

0:00:43

0:00:43

0:05:10

0:05:10

0:09:20

0:09:20

0:11:13

0:11:13

0:01:55

0:01:55

0:01:39

0:01:39

0:02:04

0:02:04

0:13:21

0:13:21

0:05:25

0:05:25

0:01:18

0:01:18

0:04:26

0:04:26

0:04:20

0:04:20

0:00:34

0:00:34

0:05:35

0:05:35