filmov

tv

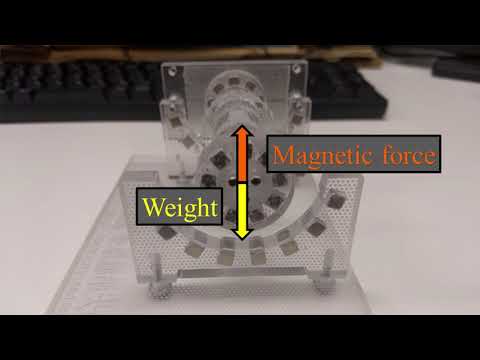

Magnetic Bearing on 3D Printer

Показать описание

3D printed magnetic bearing

Magnetic Bearing on 3D Printer

3D Printed Magnetic Bearings Confirmed

1874 Maglev Versus Thrust Bearing

How this magnetic transmission works?

KEBA – Magnetic Bearing Technology for Turbo Systems, Magnetlager-Technologie für Turbo-Maschinen

Magnetic Bearing Operating Principle and Components

Magnetic bearing

Precision Magnetic bearing

Flywheel with magnetic bearing

Simple 3D Printed Ball Bearing Car With Magnetic Repulsion Launcher

magnetic bearing fans are neat

DCLCM Magnetic Bearing Chiller | Dunham Bush | 3D

simple magnetic bearing motor

Magnetic Gears - Why Nobody Talks About This?

magnetic bearing details

1469 A 3D Printed Pelton Wheel On Magnetic Bearings

3D printed magnetic bearing first test / lozysko magnetyczne druk 3D pierwszy test

Passive Magnetic Bearing Short Demo 2022 - 11kg Rotor / Shaft

Gearless Magnetic Transmission - You Can't Break These Gears

Prototype Magnetic-Bearing-Oldham coupler for Z axis, full test stack

Make USEFUL 3D Prints with THIS List of Hardware

A Magnetic Bearing Made With Permanent Magnets

printed WITHOUT support #shorts

Комментарии

0:01:35

0:01:35

0:01:34

0:01:34

0:02:23

0:02:23

0:09:14

0:09:14

0:08:25

0:08:25

0:02:53

0:02:53

0:01:07

0:01:07

0:00:39

0:00:39

0:00:08

0:00:08

0:01:07

0:01:07

0:00:41

0:00:41

0:02:54

0:02:54

0:04:25

0:04:25

0:00:18

0:00:18

0:12:26

0:12:26

0:00:50

0:00:50

0:04:05

0:04:05

0:00:50

0:00:50

0:00:21

0:00:21

0:08:04

0:08:04

0:00:19

0:00:19

0:24:54

0:24:54

0:02:27

0:02:27

0:01:00

0:01:00