filmov

tv

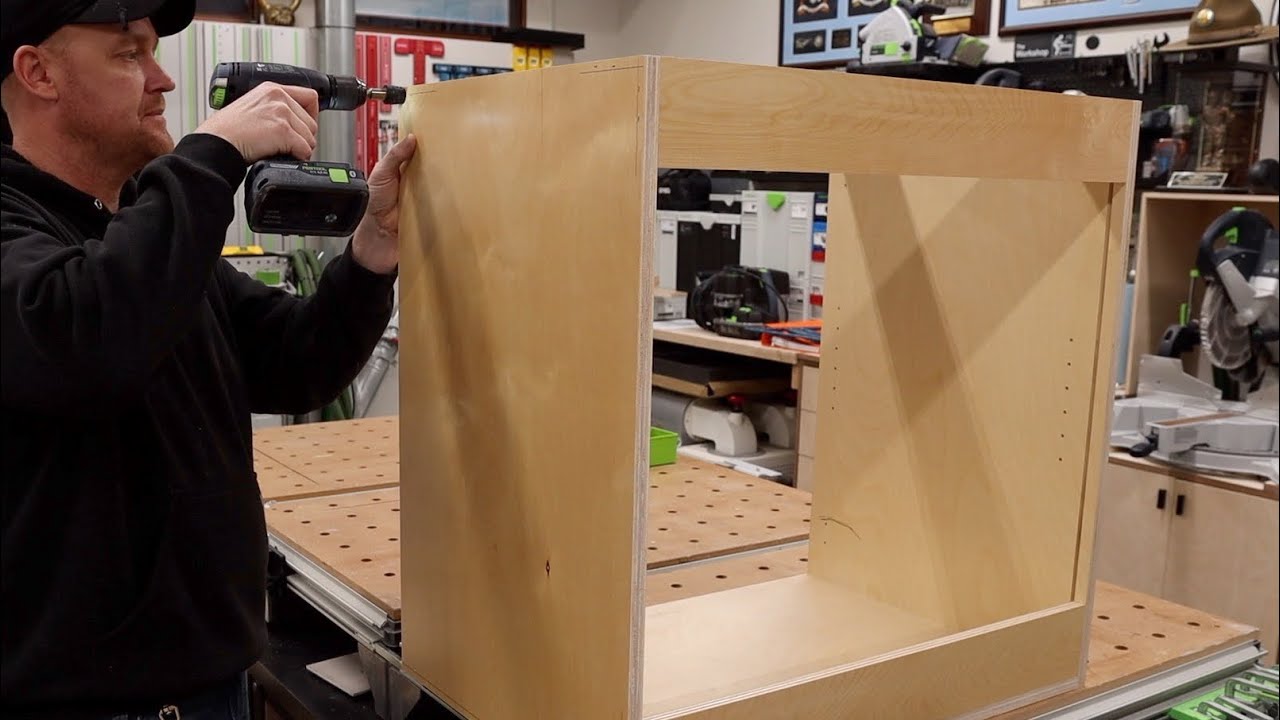

STOP overbuilding cabinets

Показать описание

In this video I will walk you through how I break down my cabinet parts and how I assemble the cabinets. There are many ways to assemble cabinets, many times more complicated than needed. This is a simple way to do a task that is so daunting to so many.

#cabinets #cabinetry #cabinetbuilding

Links to tools seen in this video. Disclaimer: As an Amazon Associate, I earn from qualifying purchases.

Sponsored By:

Affiliate For:

Partnered With:

Find me on social media!

These videos are for entertainment purposes only. Bent's Woodworking is not responsible for any viewer trying to recreate something demonstrated in this video. Attempting any of the techniques shown are at the viewers own risk.

#cabinets #cabinetry #cabinetbuilding

Links to tools seen in this video. Disclaimer: As an Amazon Associate, I earn from qualifying purchases.

Sponsored By:

Affiliate For:

Partnered With:

Find me on social media!

These videos are for entertainment purposes only. Bent's Woodworking is not responsible for any viewer trying to recreate something demonstrated in this video. Attempting any of the techniques shown are at the viewers own risk.

STOP overbuilding cabinets

STOP struggling to get level cabinets

Stop Using Plywood To Make Cabinets!

STOP overbuilding cabinets! I built a castom shelf!

This is why people don't make cabinets anymore.

DON'T USE 3/4' PLYWOOD If You Don't Need It...TRY THIS! (1/2' Plywood Vs. 3/4&ap...

Why I may never build cabinets again.

Build Cabinets The Easy Way | How to Build Cabinets

Cabinetry Basics Part 1 [video 435]

Bad Beginner Cabinet Tips

Stop trying to use every inch

I can't believe building custom cabinets was this easy

How to Build Kitchen Cabinets | START TO FINISH

Basic Cabinet Making [Compilation]

Making a Tall Storage Cabinet

You're overthinking it

How I DIYed our KITCHEN CABINETS! 🛠️ #kitchendesign

Tutorial: How to make a Shaker Style cabinet door.

Hanging cabinets on a French cleat. #cabinet #cabinetmaker

How to build cabinets in ONE day // Easy DIY cabinets for beginners

How to Build a Simple Cabinet #cabinetmaking

Simple Cabinet Building With Kreg

Quick Tip For Installing Upper Cabinets

How to Build Cabinet Built-Ins from Scratch DIY How-To with @ComeStayAwhile

Комментарии

0:15:13

0:15:13

0:10:06

0:10:06

0:29:45

0:29:45

0:06:38

0:06:38

0:08:47

0:08:47

0:05:24

0:05:24

0:07:13

0:07:13

0:20:57

0:20:57

0:08:20

0:08:20

0:24:21

0:24:21

0:13:04

0:13:04

0:11:18

0:11:18

0:16:51

0:16:51

2:22:53

2:22:53

0:08:58

0:08:58

0:08:52

0:08:52

0:01:00

0:01:00

0:01:00

0:01:00

0:00:17

0:00:17

0:34:04

0:34:04

0:00:34

0:00:34

0:00:45

0:00:45

0:00:53

0:00:53

0:00:31

0:00:31