filmov

tv

Soldering 101 - 6. Soldering a Wire to a Terminal

Показать описание

This video will teach you how to solder a wire to the terminal of a switch.

Soldering 101 - 6. Soldering a Wire to a Terminal

iFixit's Soldering 101: Beginners Guide

Soldering 101 - An Intro to Basic Soldering

Desoldering | Soldering Basics | Soldering for Beginners

Soldering tips and tricks - Tip5 Don't try to solder a wire when flux from solder was evapora...

How to solder two wires perfectly together

Soldering 101

Soldering 101

Soldering 101 - 5. Soldering a Wire to a Board

Soldering 101 - The Basics

How to reliably solder wires to PCB board #diyua

How to Solder to the top of a Guitar Pot 👍 #guitarmods #guitarist

Using Flux | Soldering Basics | Soldering for Beginners

How To Solder Wires Together Like A Pro #shorts

Walkthrough: Soldering 101

Soldering 101.

How to Solder Wires Together (Best tips and tricks)

Basic Skills!: Basic Soldering

See more Guitar Soldering tips on our Channel ‘Radioshop Pickups’ 👍 #soldering #guitarmods

Soldering 101

7 Stupid Errors in soldering with tips

Basic Soldering Technique

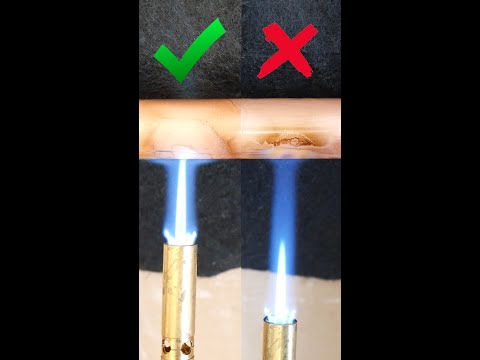

SOLDERING MISTAKE #6 (flame position)

How to Solder Copper

Комментарии

0:03:17

0:03:17

0:06:46

0:06:46

0:02:39

0:02:39

0:03:20

0:03:20

0:00:47

0:00:47

0:00:59

0:00:59

0:13:55

0:13:55

0:05:49

0:05:49

0:04:13

0:04:13

0:12:19

0:12:19

0:00:09

0:00:09

0:00:20

0:00:20

0:03:25

0:03:25

0:00:17

0:00:17

0:11:26

0:11:26

0:06:11

0:06:11

0:12:28

0:12:28

0:02:03

0:02:03

0:00:29

0:00:29

0:06:10

0:06:10

0:08:07

0:08:07

0:04:59

0:04:59

0:00:52

0:00:52

0:00:41

0:00:41