filmov

tv

Khafre's Diorite Statue

Показать описание

We examine the famous diorite statue of Khafre/Chephren with microscopy to try and determine how it was polished

Khafre Enthroned: The 4,500-Year-Old Secret Behind Its 700-Mile Journey | Egypt Detectives

Impossible Engineering: The Valley Temple of Khafre | Ancient Architects

Why Were Archaeologists So Puzzled By This Ancient Statue? | Egypt Detectives | Unearthed History

The Masterpiece of Khafre

The Middle Pyramid Megalithic Complex - Vastly Ancient, was this the FIRST to be Built at Giza?

Ancient Technology on the Giza Plateau - Part 1: The Valley Temple of Khafre

Mysterious statues of Ancient Egypt (Parte 2)

Pre-Egyptian Technology Left By an Advanced Civilization That Disappeared

The valley temple of king Khafre 4K.Exploration of the Valley Temple of and the Great Sphinx in Giza

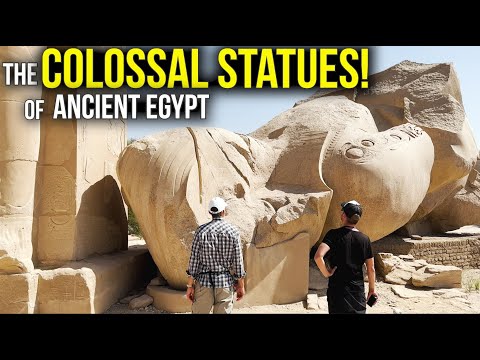

Colossal Statues of Luxor

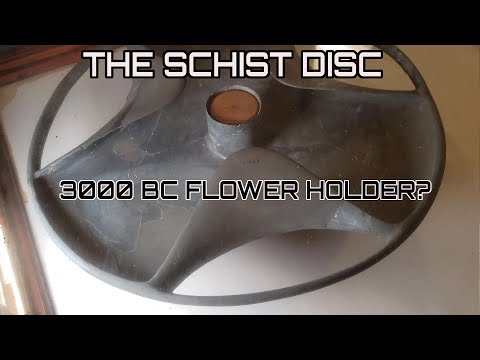

Prince Sabu's disc ( Schist disc )

Great Sphinx: Buried Secret Exposed

Cairo Museum of Antiquities, the Treasures of Ancient Egypt

Great Pyramid & Khafre Pyramid WHAT THEY ARE & ARE NOT!

Scientists Finally Unlocked The Secret Chamber Hidden Inside Egypt's Great Pyramid

Ka-aper | 4500-Years-Old Unique Wooden Egyptian Statue 🇪🇬

La Stele di re Nectanebo I

THIS Ancient Egyptian Saw-Cut Proves They Had a Lost Technology

The New Discovery in Egypt That Scares Scientists!

I'M INSIDE AN ANCIENT EGYPTIAN TOMB!! (How did they move these 100 ton stones? Giants?) 🇪🇬...

'Impossible' Architecture of Granite Temple (Giza Pyramid Complex)

Lost Ancient Technology: The Colossal Statues of Ancient Egypt

Most Fascinating Egyptian Statue Ever Made

Egyptian Lost Technology Khemit Tour 2022 - Part 1

Комментарии

0:23:29

0:23:29

0:10:05

0:10:05

0:47:30

0:47:30

0:04:43

0:04:43

0:52:54

0:52:54

0:23:22

0:23:22

0:00:44

0:00:44

1:56:00

1:56:00

0:09:02

0:09:02

0:00:10

0:00:10

0:02:48

0:02:48

0:19:26

0:19:26

0:51:33

0:51:33

0:29:54

0:29:54

1:06:04

1:06:04

0:07:10

0:07:10

0:04:42

0:04:42

0:09:54

0:09:54

0:32:04

0:32:04

0:16:29

0:16:29

0:25:19

0:25:19

0:56:27

0:56:27

0:03:34

0:03:34

0:22:54

0:22:54