filmov

tv

How to Make a Wooden Straight Edge for Woodworking

Показать описание

Joshua Farnsworth shows how to use hand tools to make a wooden straight edge, one of the most important tools in a workshop...see the full tutorial, tool brands, & photos here:

How to make a very simple wooden frame

How to make a Wooden Star (detailed)

Bamboo Creations With Wooden Craft #bamboo #Toy #Diy

Making fondant look like wood #shorts

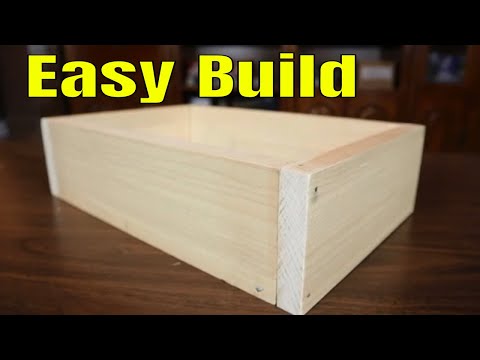

How To Make A Wooden Box For Beginners ( The Simple Way )

Why buy it when you can build it? #tooltips #diy #woodwork #wood #woodworking #tips

This guy has the guts to make toys made of wood by hand

Creativity from wood | The best wood art #wood #bamboo @Bambooidea

How I made a miniature wooden spoon

How To Make A Simple Wooden Box

carving a spoon out of almond wood!

Make a Simple Wooden Spatula - Free Pattern on my Site

Make a Fancy Phone Stand

Making A HOMEMADE Baseball Bat ⚾️

Handmade a New style wooden crossbow # Craft # DIY # Cool idea for you enjoy

DIY Wooden Coasters with Pretty Paper Napkins #decoupage #shorts

SIMPLE Way To Make A Wooden Hammer! #survival #camping #outdoors #bushcraft

How to make a Wooden Katana from hardwood flooring // Woodworking | I Like To Make Stuff

How to Make the Ultimate Wooden Clamp - Woodworking

Relax, it’s art 🪵 #carving #woodcarving #woodworking #woodworkingart #nature #relaxing

I make wooden stools. Carpenter. Professional carpenter. Rural craftsmanship. Mortise and tenon

Ebonising Oak With Vinegar and Steel Wool. #shortvideo #ebonising #woodwork

Make a Toothbrush out of Wood for Survival 🌲 #survivalhacks

Wooden Dowel Diy || Woodworking Jig #woodwork #hack #shorts

Комментарии

0:09:19

0:09:19

0:10:53

0:10:53

0:00:12

0:00:12

0:00:31

0:00:31

0:07:14

0:07:14

0:00:46

0:00:46

0:00:13

0:00:13

0:00:21

0:00:21

0:00:59

0:00:59

0:11:54

0:11:54

0:01:00

0:01:00

0:11:08

0:11:08

0:00:39

0:00:39

0:00:19

0:00:19

0:00:20

0:00:20

0:01:00

0:01:00

0:00:55

0:00:55

0:14:02

0:14:02

0:09:43

0:09:43

0:00:33

0:00:33

0:00:13

0:00:13

0:00:54

0:00:54

0:00:23

0:00:23

0:00:48

0:00:48