filmov

tv

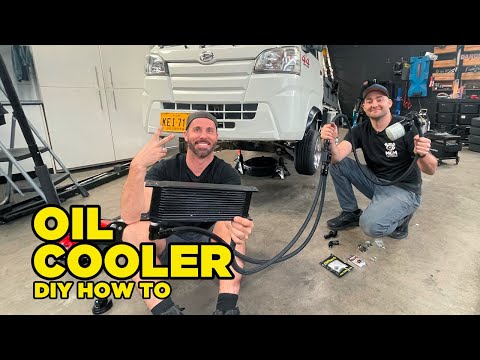

Fitting an oil cooler to Project C1

Показать описание

In today’s video, I’m installing an oil cooler onto Project C1. This is a preparatory job for the eventual turbo conversion job because as everyone knows, turbos produce heat and heat breaks down engine oil.

I bought an oil filter sandwich plate from AliExpress and has an M20 x 1.5 and a ¾ - 16 UNF filter adapter in the box. It’s made from billet aluminium and has 2x AN-10 and 2x AN-4 outputs. The only problem I encountered installing this was my own stupidity by installing it upside down!

I’m using the AN-10 input & output to connect it to the oil cooler and I intend to use the AN-4 outputs to install an oil temperature/pressure gauge and the other as an oil supply to the turbo in the future. The oil cooler radiator was purchased from eBay and is a 9-row radiator with AN-10 input & outputs. I used an M6 riv nut and bolt to attach it to the crash bar structure. If I were to stop at the oil cooler installation, I’d have mounted it underneath the crash bar, but because I’ll need an intercooler for the forced induction air intake, I’ll need that space to mount the intercooler and turbo, so it had to go above the crash bar. This caused bumper fitment problems which I’d fixed off camera and after installation, but isn’t really a big deal because I’ll soon be replacing the front bumper with a face lift bumper, modified so that it is fit for turbo purposes.

I also bought some AN-10 brained hose and some straight & 90 degree AN-10 connectors. This was my first time in assembling AN hose, so I found it a little difficult at first. I used masking tape to wrap around the hose braid at the area that I needed to cut it and then used an angle grinder with a cutting disc installed to cut through the pipe as straight as I could. I then used some red rubber grease to lubricate the inside of the connector, so that it slips over the end of the hose and buts up against the locking collar. I then tightened the locking collar as tight as I dare (steel spanner vs aluminium fitting) and then installed them into the car. I have also kept these hoses together with 2x AN-10 hose clamps.

Installing an oil cooler has increased the oil system capacity by what I estimate to be somewhere in the region of 0.3-0.4 litres, which brings the total figure to approximately 4 litres. This isn’t a bad thing because there is more oil in the lubrication system of the engine, still uses the same size of oil filter and it is still within the capacity of a standard sized oil bottle form an auto parts shop, keeping oil changes cheap and easy.

Don’t forget to follow my sponsors:

• TSA Performance on Instagram @tsaperformance for everything you’ll need to make your 1KR engine perform as it should.

• Form 7 Performance for all your aftermarket parts needs for almost any vehicle, @form7performance on Instagram, using code ‘DABDIY’ at checkout.

• X8R on Instagram @x8rlimited, using discount code ‘DABDIY20’ at checkout.

• Mishimoto, @mishimoto on Instgram.

I bought an oil filter sandwich plate from AliExpress and has an M20 x 1.5 and a ¾ - 16 UNF filter adapter in the box. It’s made from billet aluminium and has 2x AN-10 and 2x AN-4 outputs. The only problem I encountered installing this was my own stupidity by installing it upside down!

I’m using the AN-10 input & output to connect it to the oil cooler and I intend to use the AN-4 outputs to install an oil temperature/pressure gauge and the other as an oil supply to the turbo in the future. The oil cooler radiator was purchased from eBay and is a 9-row radiator with AN-10 input & outputs. I used an M6 riv nut and bolt to attach it to the crash bar structure. If I were to stop at the oil cooler installation, I’d have mounted it underneath the crash bar, but because I’ll need an intercooler for the forced induction air intake, I’ll need that space to mount the intercooler and turbo, so it had to go above the crash bar. This caused bumper fitment problems which I’d fixed off camera and after installation, but isn’t really a big deal because I’ll soon be replacing the front bumper with a face lift bumper, modified so that it is fit for turbo purposes.

I also bought some AN-10 brained hose and some straight & 90 degree AN-10 connectors. This was my first time in assembling AN hose, so I found it a little difficult at first. I used masking tape to wrap around the hose braid at the area that I needed to cut it and then used an angle grinder with a cutting disc installed to cut through the pipe as straight as I could. I then used some red rubber grease to lubricate the inside of the connector, so that it slips over the end of the hose and buts up against the locking collar. I then tightened the locking collar as tight as I dare (steel spanner vs aluminium fitting) and then installed them into the car. I have also kept these hoses together with 2x AN-10 hose clamps.

Installing an oil cooler has increased the oil system capacity by what I estimate to be somewhere in the region of 0.3-0.4 litres, which brings the total figure to approximately 4 litres. This isn’t a bad thing because there is more oil in the lubrication system of the engine, still uses the same size of oil filter and it is still within the capacity of a standard sized oil bottle form an auto parts shop, keeping oil changes cheap and easy.

Don’t forget to follow my sponsors:

• TSA Performance on Instagram @tsaperformance for everything you’ll need to make your 1KR engine perform as it should.

• Form 7 Performance for all your aftermarket parts needs for almost any vehicle, @form7performance on Instagram, using code ‘DABDIY’ at checkout.

• X8R on Instagram @x8rlimited, using discount code ‘DABDIY20’ at checkout.

• Mishimoto, @mishimoto on Instgram.

Комментарии

0:17:40

0:17:40

0:19:34

0:19:34

0:13:05

0:13:05

0:01:16

0:01:16

0:05:27

0:05:27

0:03:58

0:03:58

0:25:04

0:25:04

0:07:14

0:07:14

0:00:28

0:00:28

0:23:36

0:23:36

0:15:49

0:15:49

0:07:35

0:07:35

0:21:46

0:21:46

0:09:49

0:09:49

0:13:24

0:13:24

0:22:29

0:22:29

0:15:25

0:15:25

0:13:47

0:13:47

0:14:49

0:14:49

0:17:27

0:17:27

0:11:27

0:11:27

0:22:45

0:22:45

0:10:22

0:10:22

0:25:44

0:25:44