filmov

tv

From Broken to Fixed in Minutes | Repairing a Fridge Compressor

Показать описание

RepairClinic.com — From Broken to Fixed in Just a Few Clicks!

How Quickly Can I Fix My Broken Ankle?

Ingenious way to repair broken plastic

I Paid $2500 for 5 BROKEN High End Laptops - But Can I Fix Them?!

When Broken Is Easily Fixed

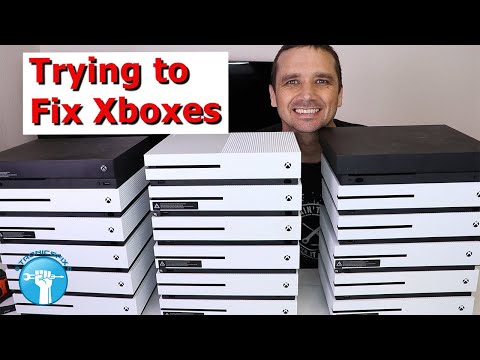

I bought 18 broken Xboxes - Can I Fix Them and Make Money?

How to repair broken bowls using Kintsugi - if broken bowls can be fixed, can so can broken hearts

How To Fix a Broken TV Screen

Broken display #repair #redminote9 #tech #androidphone #smartphone

Fixing A Broken Heart - Indecent Obsession (Lyrics)

I Bought 10 Broken iPhone X's - But Are They Fixable?

How To Assemble or Fix a Broken 3 x 3 Rubik’s Cube at Home : Super Easy Beginners Video Tutorial

Did You Know This Trick? Tips To Fix Broken Pvc Pipes Without Turning Off The Water

I Bought 5 BROKEN Xbox Series X's From eBay - But Can I Fix Them?!

How to Fix a Broken Stem [Plant Surgery] creative explained

I Bought 16 BROKEN Apple Watches - Can I fix Them?

The Cheap Way to Fix Broken Back Glass #Shorts

How to FIX Broken Makeup!

How to repair any android smart phone broken display glass LCD screen easily

Mini Blinds Broken? Fix Them For Free!!!

6 Ways to Fix Broken Wires - Beginner Through Pro

How to Repair Broken Toilet Flange

Broken Car Window Repair - Temporary fix for a broken car window! Easy to install!

DIY Luggage Repair - How to FIX Broken Luggage with Sugru

Комментарии

0:01:51

0:01:51

0:17:18

0:17:18

0:04:00

0:04:00

0:24:36

0:24:36

0:04:21

0:04:21

0:26:51

0:26:51

0:00:59

0:00:59

0:01:56

0:01:56

0:00:21

0:00:21

0:03:41

0:03:41

0:29:28

0:29:28

0:12:34

0:12:34

0:08:33

0:08:33

0:31:16

0:31:16

0:00:25

0:00:25

0:28:27

0:28:27

0:00:26

0:00:26

0:03:52

0:03:52

0:02:01

0:02:01

0:04:30

0:04:30

0:13:27

0:13:27

0:01:17

0:01:17

0:00:31

0:00:31

0:01:43

0:01:43