filmov

tv

How much Quarter Sawn Lumber CAN WE GET from ONE Log?

Показать описание

We finally got back to milling some lumber. I wonder how much we can get from this one log?

Midnight Tale by Kevin MacLeod

Welcome to the Third Time Around Ranch. After living in the country most of our lives we still felt like something was wrong. We kept talking about getting back to the basics of life and taking care of ourselves like our great grandparents did. So instead of depending on stores for everything, we bought some land in Alabama where we intend to build debt free on a fixed income and become as self sufficient as we possibly can. We are happy to have you join us as we carve out a new way of life for ourselves and our youngest son.

We would love to hear from you, you can leave us a comment or if you'd rather we love to receive mail.

Snail mail: Third Time Around Ranch

PO Box 631

Ashford, AL 36312

Midnight Tale by Kevin MacLeod

Welcome to the Third Time Around Ranch. After living in the country most of our lives we still felt like something was wrong. We kept talking about getting back to the basics of life and taking care of ourselves like our great grandparents did. So instead of depending on stores for everything, we bought some land in Alabama where we intend to build debt free on a fixed income and become as self sufficient as we possibly can. We are happy to have you join us as we carve out a new way of life for ourselves and our youngest son.

We would love to hear from you, you can leave us a comment or if you'd rather we love to receive mail.

Snail mail: Third Time Around Ranch

PO Box 631

Ashford, AL 36312

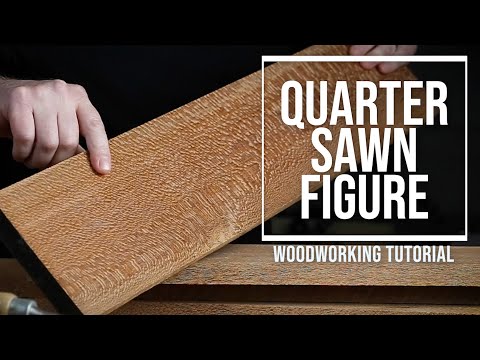

The Characteristics of Quarter Sawn White Oak Wood

Quarter Sawn vs Rift Sawn vs Plain Sawn White Oak - Features & Benefits | RTA Cabinet Options

Quarter vs Rift vs Plain Sawn Lumber - What’s the Difference? #Shorts

Plain vs Quarter vs Rift Sawn Lumber - Osborne Insider

Quarter sawn lumber is more expensive than plain sawn. #woodworking #furniture

All About Quarter Sawing: Sycamore Lumber For Flooring!

Tips & Tricks Quarter Sawn Lumber

Better Red Oak - Rift Sawn

Bookmatched and Quarter Sawn White Oak #boards #bookmatch #sawmill #business #local #happyvalley

What Does Quarter Sawn Sycamore Look Like? BEAUTIFUL!

The Fastest, Best Hands Off Quarter Sawing (You've Ever Seen!)

Quarter Sawing Huge Oak Log!

Explanation of Rift, Flat, and Quarter Sawn Wood

What is rift-sawn hardwood flooring? & Why is it so popular?

Massive Tree to Quarter Sawn Wood Using a Portable Bandsaw Mill

Classic quarter-sawn white oak, right here!

Why Quarter Sawn Red Oak is Worth= $$$

How to Quarter Saw Lumber, The Old Way? Or the New Way?

Quarter Sawn Lumber - Everything You Need to Know

This is what Rift sawn white oak looks like.

Rift Sawn White Oak - Buying Lumber at the Lumberyard

4 Main Methods of Quarter Sawing Explained. #quartersawn #quartersawingmethod

What is QUARTER SAWN Lumber?

Plain Sawn Technique

Комментарии

0:02:13

0:02:13

0:09:32

0:09:32

0:00:46

0:00:46

0:02:16

0:02:16

0:00:56

0:00:56

0:10:17

0:10:17

0:10:03

0:10:03

0:04:17

0:04:17

0:00:30

0:00:30

0:00:44

0:00:44

0:12:40

0:12:40

0:00:47

0:00:47

0:00:58

0:00:58

0:04:00

0:04:00

0:14:20

0:14:20

0:00:58

0:00:58

0:01:00

0:01:00

0:37:25

0:37:25

0:10:30

0:10:30

0:00:58

0:00:58

0:07:07

0:07:07

0:01:00

0:01:00

0:06:54

0:06:54

0:00:21

0:00:21