filmov

tv

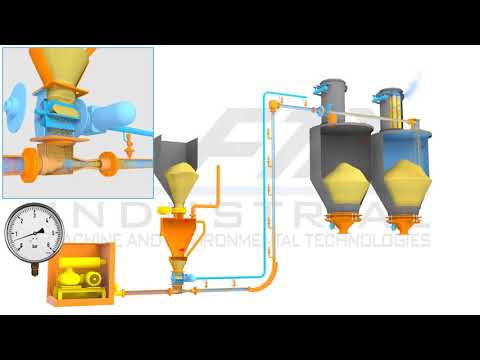

Dilute Phase Pneumatic Conveying System

Показать описание

Dense Phase

The basic concept of Dense Phase Conveying is that a pulse of air is used to force a plug of material from one point to another. The air has high pressure and low velocity. It is ideal for Higher density products or conveying longer distances. Dense phase is the best option for abrasive & pre blended products.

Dense Phase Systems can be further divided into 2 main types:

Dense Phase Pressure

The system uses a vessel to hold the material while air is injected to a set pressure. The discharge valve is opened sending a plug of material to the destination. A filter at the destination cleans the exhaust air. Most Dense Phase systems are of this type.

Key Points of Dense Phase Conveying:

Use dense phase pneumatic systems for minimum particle attrition and lowest pipe wear.

Allows higher density products to be conveyed

To make sure the this is the right

High system pressures (15 -- 90 psi)

Low air to solids loading ratios (less than 0.2)

Low velocities but high Kg capacity

Less erosion -- a result of lower velocity

Higher capital costs at startup

Pressure rated lines, valves, etc.

Packaging Systems to suit your products needs, you should talk to AWE Group sales engineers

The basic concept of Dense Phase Conveying is that a pulse of air is used to force a plug of material from one point to another. The air has high pressure and low velocity. It is ideal for Higher density products or conveying longer distances. Dense phase is the best option for abrasive & pre blended products.

Dense Phase Systems can be further divided into 2 main types:

Dense Phase Pressure

The system uses a vessel to hold the material while air is injected to a set pressure. The discharge valve is opened sending a plug of material to the destination. A filter at the destination cleans the exhaust air. Most Dense Phase systems are of this type.

Key Points of Dense Phase Conveying:

Use dense phase pneumatic systems for minimum particle attrition and lowest pipe wear.

Allows higher density products to be conveyed

To make sure the this is the right

High system pressures (15 -- 90 psi)

Low air to solids loading ratios (less than 0.2)

Low velocities but high Kg capacity

Less erosion -- a result of lower velocity

Higher capital costs at startup

Pressure rated lines, valves, etc.

Packaging Systems to suit your products needs, you should talk to AWE Group sales engineers

0:01:20

0:01:20

0:02:14

0:02:14

0:03:03

0:03:03

0:14:56

0:14:56

0:00:16

0:00:16

0:02:32

0:02:32

0:01:28

0:01:28

0:01:33

0:01:33

0:06:00

0:06:00

0:00:52

0:00:52

0:01:25

0:01:25

0:02:49

0:02:49

0:00:58

0:00:58

0:07:11

0:07:11

0:01:14

0:01:14

0:01:20

0:01:20

0:00:27

0:00:27

0:01:30

0:01:30

0:01:00

0:01:00

0:01:09

0:01:09

0:00:38

0:00:38

0:01:22

0:01:22

0:42:05

0:42:05

0:00:37

0:00:37