filmov

tv

Replacing Tracks with Network Rail

Показать описание

Network Rail invited me down to Whitstable in Kent to show me what goes on when a section of the railways is closed, and the team of orange descend onto the tracks to work non-stop to replace rails that are almost fifty years old.

My thanks to Chris from Network Rail for the invite and access. Thanks also to Daren Smith, a Construction Manaager also with Network Rail.

My thanks to Chris from Network Rail for the invite and access. Thanks also to Daren Smith, a Construction Manaager also with Network Rail.

Replacing Tracks with Network Rail

Replacing Tracks Inside The Clayton Tunnel

An Introduction to Switches & Crossings - Network Rail engineering education (12 of 15)

National Rail - Think Safe, Stay Safe

Tamping Machine - Up Close and Personal

Railway Track Laying Machine renewing a high-speed railway line

Repairing the Landport Viaduct with Network Rail

How do trains change the tracks?

Repairing Railway Landslides with Network Rail

How to Look After Our Railway _ UK Railway Maintenance - Edge Hill Depot Network Rail

How Europe's Replacing Planes With Trains

Railway Ballast Cleaning Machine on a high-speed railway line

Time Lapse - Rail Bridge Replacement, Cow Lane, Reading

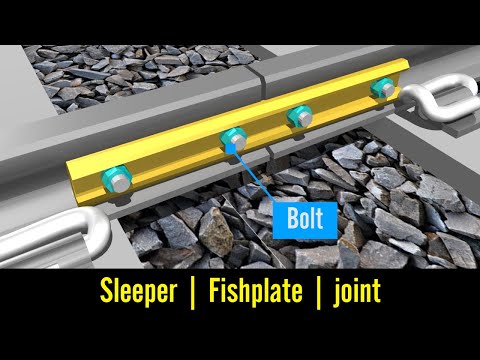

Railway Track Components | #Sleeper | #Ballast | #Joint | #fastening system | #Joggled Fishplate

A Slip Switch Railway Crossing| How Train change tracks

Time-Lapse Example: 36hr Road Bridge Demolition & Replacement

Why Are There Stones Along Railway Tracks?

Engineer Steve showcases the High Output Ballast Cleaner

🚂 Emergency Railway Track Repair ⛏️

Railway line repair with Thermite welding | train track repair

The Apprentice Experience - Network Rail

Lee Valley Rail Programme - installing the first 3km of a new track

'Box structure' flyover replacement saves £70m

Extreme Train Railway Tracks Replacement Modern Technology - Amazing Rail Building Machines 2021

Комментарии

0:10:30

0:10:30

0:08:41

0:08:41

0:07:05

0:07:05

0:00:31

0:00:31

0:00:28

0:00:28

0:07:33

0:07:33

0:08:20

0:08:20

0:06:06

0:06:06

0:11:43

0:11:43

0:06:04

0:06:04

0:08:39

0:08:39

0:05:29

0:05:29

0:04:00

0:04:00

0:03:48

0:03:48

0:04:32

0:04:32

0:05:49

0:05:49

0:05:31

0:05:31

0:02:09

0:02:09

0:06:12

0:06:12

0:09:01

0:09:01

0:05:12

0:05:12

0:01:52

0:01:52

0:02:28

0:02:28

0:22:43

0:22:43