filmov

tv

Building A Race Car Frame: How To Not Die At 200 MPH

Показать описание

Superfast Matt is supported by:

Building A Race Car Frame: How To Not Die At 200 MPH

Tube Chassis Race Car Build Pt.7 Big Wing Install!

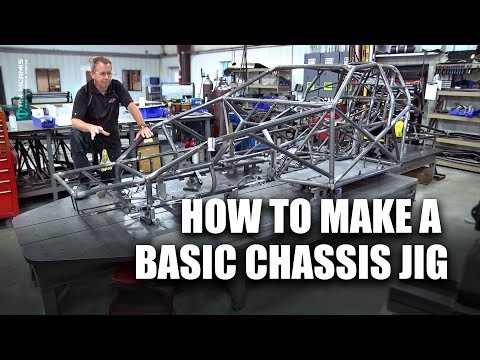

How To Make A Basic Chassis Jig

An inside look at Precision Built Race Cars' fabrication shop

Intro to Vintage Race Car Chassis Design

How to Build a Formula 1 Car - Chassis Design - Ep1

Tube Frame Race Car Build Ep.11

Fabricating Race Car Frame from Scratch: Building a 1930s Single Seater!

BUICK INDIE RACER #CUSTOM BUILD

Race Car Suspension Fabrication

Replacing My Mom's Civic With a TUBE CHASSIS Race Car!

From Sheet Metal to Suspension! - Road Race Chassis for the Hot Rod Rebuild

Ep. 8 Shop Car Tube Front Fabrication!

Building A New Race Car

Learning Chassis Fabrication from a PRO | Mullis Race Cars

DIY SUPER CAR!

How a NASCAR Cup Series Race Car Works

1930's RACE CAR COMPLETE BUILD (201 Days in 25 Minutes)

Tube notching & fabrication tool kit! Perfect for roll cages and race cars of all kinds.

Subaru Race Car Build, Chassis is done! The engine is finally in!

How to Make Fibreglass/Carbon Fibre Race Car Bodywork - Part 1/2

Seam Welding Race Cars

Engine Is In! Tube Chassis Race Car build Ep.15

Mopro Sports visits X1 Race Cars

Комментарии

0:16:10

0:16:10

0:09:24

0:09:24

0:06:50

0:06:50

0:02:26

0:02:26

0:28:09

0:28:09

0:09:06

0:09:06

0:12:11

0:12:11

0:36:55

0:36:55

0:01:01

0:01:01

0:18:01

0:18:01

0:18:08

0:18:08

0:16:44

0:16:44

0:25:37

0:25:37

0:19:16

0:19:16

0:11:09

0:11:09

0:00:17

0:00:17

0:19:33

0:19:33

0:27:46

0:27:46

0:00:41

0:00:41

0:03:15

0:03:15

0:04:32

0:04:32

0:06:49

0:06:49

0:10:03

0:10:03

0:03:12

0:03:12