filmov

tv

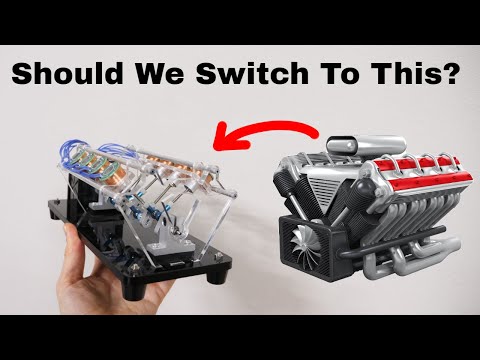

solenoid engine

Показать описание

What to do during Coronavirus lockdown? I had this solenoid laying around - it is from our Generac generator - in which it was so weak under cranking voltage that it often failed to open the gas valve, preventing the generator from starting. The diagnosis of THAT took quite a while - but ultimately Generac supplied a stronger solenoid and all is well with the generator. But I digress.

So I had this spare solenoid, and I just couldn’t get the idea of building an "engine" from it and other scrap parts off my mind. I couldn't bring myself to design everything in advance - without knowing a good technical drawing program and being unable to draw so many components in a cohesive drawing! So I just started making pieces and parts until I had the whole thing working. The switch mount is machined from solid aluminum. The flywheel is brass. The shaft, crank pin, connecting rod, pistons and pins are steel. I made the aluminum cam by starting with a round part, guessing and removing material with a belt sander. It is fixed to the shaft with a setscrew that lets me adjust the switch timing relative to top dead center. The switch doesn’t open and close at exactly 180 degrees, but the microswitch has both normally open and normally closed contacts, so I could choose “slightly more”or “slightly less” than 180. (By slightly I mean about 20 degrees - the cam having been made very UN-engineeringly, by eye and gut instinct.) The solenoid/“cylinder” wasn’t made to be precise and the magnetic pull isn't very strong, so it needs a little slop between the piston and the cylinder - as well as a groove to vent the vacuum/compression of the reciprocating motion. Between that, the load from the effort required to operate the switch, and friction - the it just barely runs. In fact, it wouldn’t quit keep running at 13.8 VDC - but my power supply maxes at 17.5 and that’s what you’re seeing here. But run it does..... It was a good project that required a good deal of precision work. (For example, the useful travel of the solenoid is minimal, and is strongest at the bottom of throw - I mounted it so that it was bottoming out slightly, then removed .010” at a time from the bottom of the piston until it just didn’t.)

Anyway - proud of myself. Another useless object that consumed a lot of time and thinking!

0:12:20

0:12:20

0:06:30

0:06:30

0:01:00

0:01:00

0:00:12

0:00:12

0:00:15

0:00:15

0:00:15

0:00:15

0:16:10

0:16:10

0:12:57

0:12:57

0:00:07

0:00:07

0:00:22

0:00:22

0:00:13

0:00:13

0:19:04

0:19:04

0:01:29

0:01:29

0:11:27

0:11:27

0:09:21

0:09:21

0:06:08

0:06:08

0:07:17

0:07:17

0:00:17

0:00:17

0:05:55

0:05:55

0:00:48

0:00:48

0:08:20

0:08:20

0:00:26

0:00:26

0:08:53

0:08:53

0:01:00

0:01:00