filmov

tv

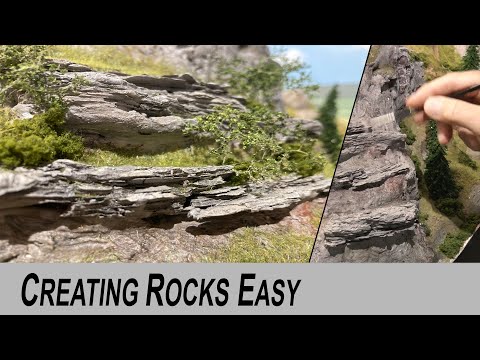

How to make rocks using Rebar Lath part 1

Показать описание

This complete comprehensive course is designed to fully train you without having to attend any classes. Perfect for the person who is unable to travel to one of our locations but wants to learn the JPJ Technologies, Inc. methods, techniques and formulas.

JPJ Technologies, Inc. provides you the formulas, trade secrets and procedures. We do not sell or require you to buy any pre-packaged products!

Training Includes:

All of the Formulas, Techniques, Procedures, and Trade Secrets for:

– Rebar and lath construction

– Liner construction with faux/synthetic rock

– Four types of solid fill construction

– Cardboard rock construction (BIG savings on material and labor!)

– Earthen rock construction (BIG savings on material and labor!)

– Recycled rock construction (BIG savings on material and labor!)

– Molding and casting from molds

– Building with polyurethane and all other foams such as polyester, epoxy and every other material used to create any type of synthetic rock you can imagine

– Creating your own synthetic lightweight rock panels and rocks as well as how to join the panels together

– Design and construction techniques for component, portable and lightweight features

– Synthetic rock on horizontal surfaces using overlay systems, carved systems and stamped concrete installed for as low as 10 cents per square foot (perfect for renewing existing patios, walkways and driveways!)

– Designer concrete countertops and flooring including forming, pouring, polishing, staining and sealing

– Faux rock retaining wall systems

– Faux stone on vertical surfaces including how to resurface almost any feature

– Creating scenic areas and design layouts that are functional yet natural

– Eleven custom texturing, 11 staining processes and five seal coating techniques

– Water feature techniques including instruction about biological filters for ponds, waterfalls, boulder swimming pools and spas

– Building in freeze and thaw climates successfully

– Pumps, electrical, plumbing, filtration, and lighting and explanation of the biological and chemical processes

– Marketing, sales, estimating, running personnel and installation crews

JPJ Technologies, Inc. provides you the formulas, trade secrets and procedures. We do not sell or require you to buy any pre-packaged products!

Training Includes:

All of the Formulas, Techniques, Procedures, and Trade Secrets for:

– Rebar and lath construction

– Liner construction with faux/synthetic rock

– Four types of solid fill construction

– Cardboard rock construction (BIG savings on material and labor!)

– Earthen rock construction (BIG savings on material and labor!)

– Recycled rock construction (BIG savings on material and labor!)

– Molding and casting from molds

– Building with polyurethane and all other foams such as polyester, epoxy and every other material used to create any type of synthetic rock you can imagine

– Creating your own synthetic lightweight rock panels and rocks as well as how to join the panels together

– Design and construction techniques for component, portable and lightweight features

– Synthetic rock on horizontal surfaces using overlay systems, carved systems and stamped concrete installed for as low as 10 cents per square foot (perfect for renewing existing patios, walkways and driveways!)

– Designer concrete countertops and flooring including forming, pouring, polishing, staining and sealing

– Faux rock retaining wall systems

– Faux stone on vertical surfaces including how to resurface almost any feature

– Creating scenic areas and design layouts that are functional yet natural

– Eleven custom texturing, 11 staining processes and five seal coating techniques

– Water feature techniques including instruction about biological filters for ponds, waterfalls, boulder swimming pools and spas

– Building in freeze and thaw climates successfully

– Pumps, electrical, plumbing, filtration, and lighting and explanation of the biological and chemical processes

– Marketing, sales, estimating, running personnel and installation crews

Комментарии

0:00:19

0:00:19

0:05:07

0:05:07

0:00:56

0:00:56

0:01:01

0:01:01

0:09:31

0:09:31

0:08:41

0:08:41

0:00:19

0:00:19

0:14:04

0:14:04

0:00:59

0:00:59

0:11:51

0:11:51

0:14:02

0:14:02

0:00:17

0:00:17

0:00:57

0:00:57

0:23:01

0:23:01

0:14:48

0:14:48

0:23:13

0:23:13

0:00:23

0:00:23

0:00:50

0:00:50

0:13:58

0:13:58

0:00:25

0:00:25

0:00:22

0:00:22

0:04:45

0:04:45

0:08:01

0:08:01

0:08:44

0:08:44