filmov

tv

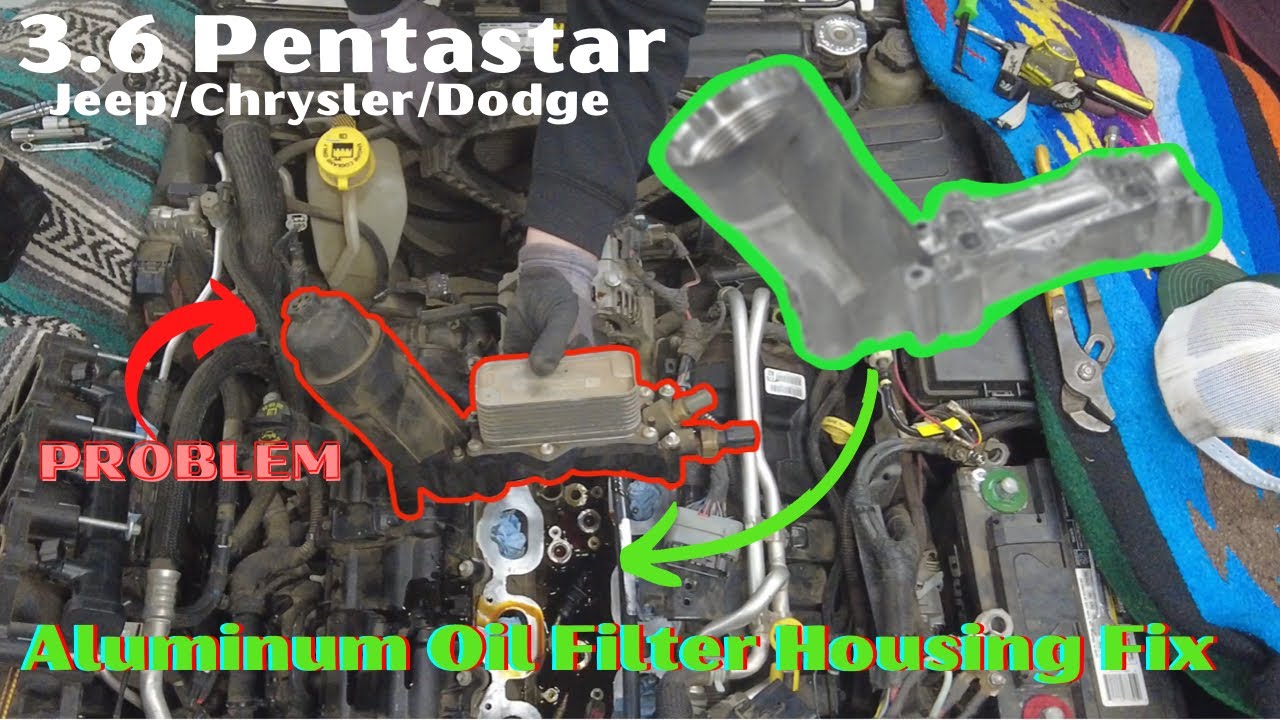

Jeep Wrangler JK JKU - Oil Cooler Filter Housing Replacement 3.6L Pentastar Doorman 926-876

Показать описание

Hey what’s up guys in this video we’re going to be replacing a leaky oil cooler filter housing on my 2015 Jeep Wrangler JK. I hate leaks of any kind and this one tops them all. In this video I’m going to share with you how I tear down the 3.6 Pentastar engines top end to replace the leaky housing with a Doorman upgraded (926-876) all aluminum housing and new gasket set. From Start to finish, let’s get to work. 🍻

Parts and tools list

DISCLAIMER

Due to the factors out of control by ATEM OFFROAD, we cannot guarantee against improper use or unauthorized modifications of this information ATEM OFFROAD assumes no liability or responsibility for property damages or injuries incurred as a result of any information contained in this video. Use this information at your own risk . ATEM OFFROAD recommends safe practices when working on vehicles and or with tools seen in this video, any injury damage or loss that may result from improper use of these tools equipment or from the information contained in this video

Is the sole responsibility of the user and not ATEM OFFROAD. Be Safe

This video and description contains affiliate links which means if you click on one of these product links, I’ll receive a small commission. Thank you

Parts and tools list

DISCLAIMER

Due to the factors out of control by ATEM OFFROAD, we cannot guarantee against improper use or unauthorized modifications of this information ATEM OFFROAD assumes no liability or responsibility for property damages or injuries incurred as a result of any information contained in this video. Use this information at your own risk . ATEM OFFROAD recommends safe practices when working on vehicles and or with tools seen in this video, any injury damage or loss that may result from improper use of these tools equipment or from the information contained in this video

Is the sole responsibility of the user and not ATEM OFFROAD. Be Safe

This video and description contains affiliate links which means if you click on one of these product links, I’ll receive a small commission. Thank you

Комментарии

0:20:47

0:20:47

0:10:11

0:10:11

0:11:51

0:11:51

0:01:48

0:01:48

0:08:29

0:08:29

0:22:39

0:22:39

0:01:53

0:01:53

0:07:02

0:07:02

0:22:55

0:22:55

0:05:43

0:05:43

0:00:16

0:00:16

0:07:57

0:07:57

0:00:30

0:00:30

0:21:56

0:21:56

0:06:57

0:06:57

0:00:31

0:00:31

0:11:09

0:11:09

0:09:21

0:09:21

0:01:18

0:01:18

0:06:05

0:06:05

0:09:37

0:09:37

0:06:27

0:06:27

0:06:26

0:06:26

0:08:07

0:08:07